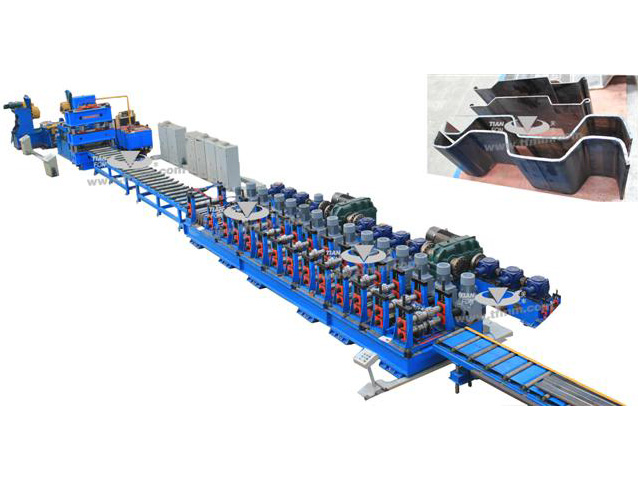

One, the production line

1, the production line

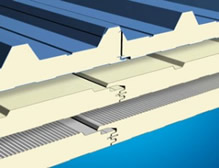

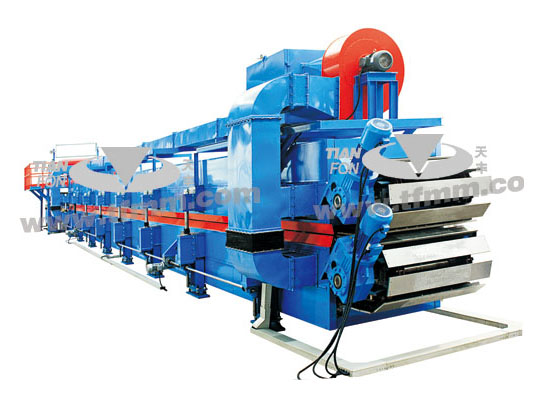

Polyurethane sandwich panel continuous production line for decoiling, cut off the docking, laminating and embossing/molding, preheating, foaming, continuous curing, cutting, stacking, packing, and other functions, high degree of automation, stable performance.

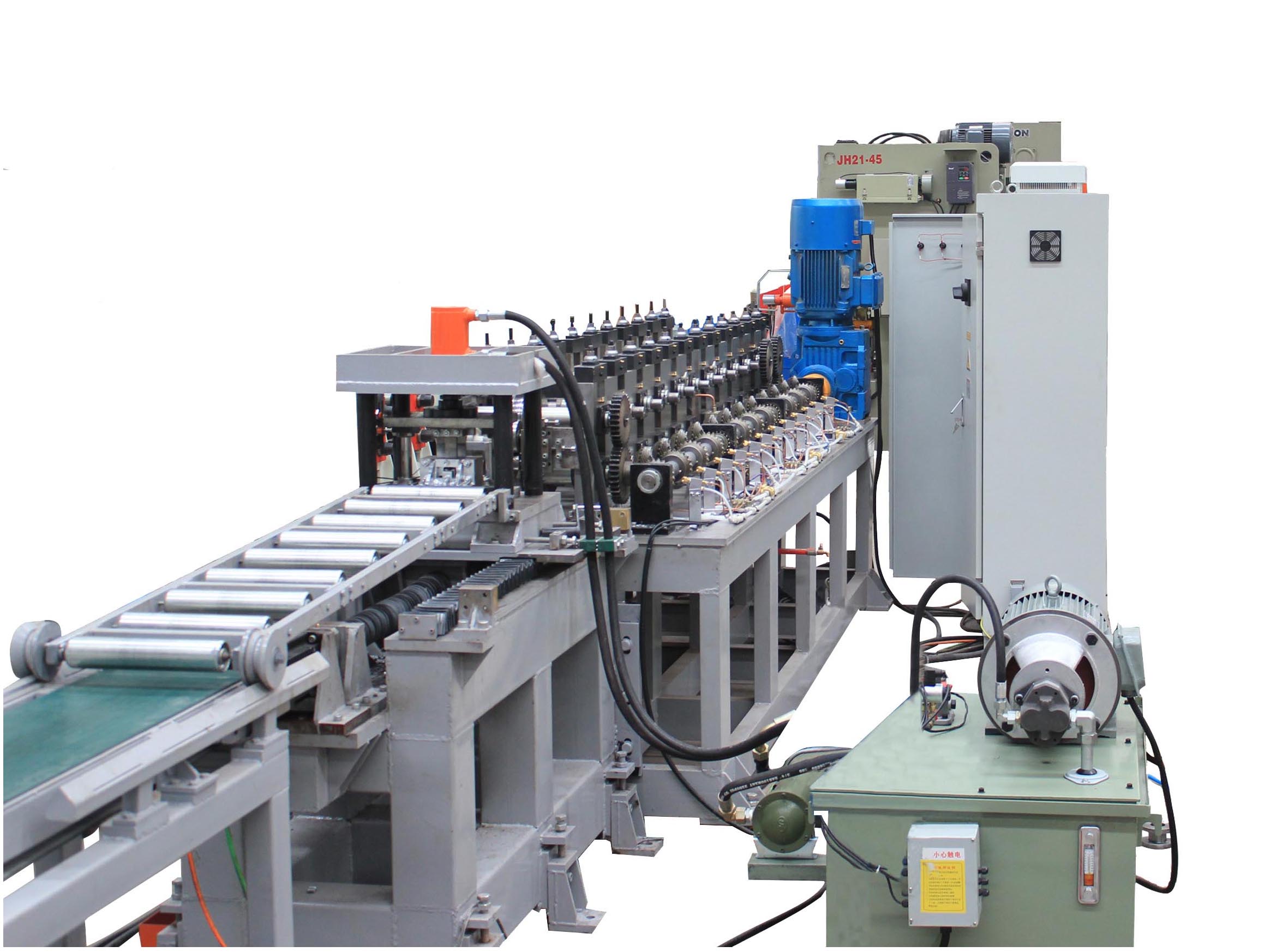

Open-book area: there are many sets of decoiler, roller conveyer, lead to send machine, shearing machine, laminating machine and other equipment for the upper and lower two layers of roller forming machine conveyor plate.

Sheet forming area: there are two layers of roller pressure molding equipment and rapidly changing institutions, to produce various shapes of plate type, meet the needs of the customer diversification.

Foaming area: there are high-pressure polyurethane foam machine, casting machine, double track of laminating machine and other equipment.

Feeding polyurethane foam machine, with electronic measuring devices, automatic feeding system, ensure completely according to the ratio of raw materials, spray evenly mixed; Double crawler machine Is equipped with precise and reliable temperature control system of foaming process, ensure uniform foam plank, dense, firm bonding.

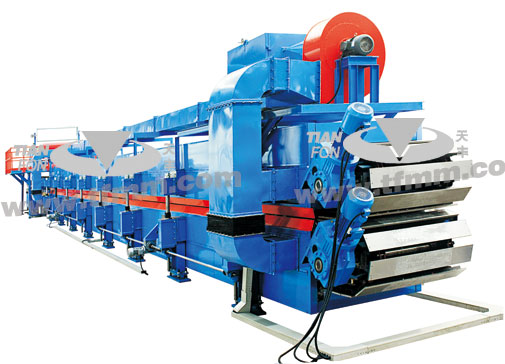

Polyurethane equipment double crawler laminating machine

Polyurethane equipment high pressure foaming machine

Sawing area: a follow-up sawing machine and the edge milling machine, plate length cut.

Pallet packing area: a quick turnover, pallet, roller conveyer, automatic packaging system equipment such as composition, can complete plate conveyor, flip, move, packaging, and other functions, improve the efficiency of production line, product packaging effect is good, guarantee products in production and transportation process without damage;

Polyurethane equipment pallet, packaging parts

Automation control system: this production line is equipped with Siemens control system, the humanized operation interface is convenient for operation, monitoring, advanced computer control, the whole line parameter adjustment is convenient, effectively guarantee the stable, efficient operation of the production line. This production line is designed in the digestion and absorption of advanced foreign technology, the production line running reliable, high degree of automation, with international advanced level.

Second, the main technical parameters of production line

1, technical parameters

Molding part:

卷钢板种类 | 彩涂钢板或不锈钢板 |

钢板厚度 | 0.35~0.6mm |

卷钢重量 | 最大为10T /7.5T(可选) |

卷钢宽度 | 最大为1,250mm |

卷钢内径 | 标准为 ?508mm |

卷钢外径 | 最大为 ?1100mm |

生产线速度 | 1.5~12m/min |

压缩空气 | 最大为4~9kg/ |

电力 | 380v,50Hz |

操作高度 | 地面起1,300mm |

Sandwich board:

夹芯板种类

| 屋顶用及建筑/冷库墙体用 ① 屋顶板; ② 冷库板; ③ 墙面板; |

最短为3,000mm 最长为15,000mm | |

夹芯板宽度 | 在600~1,000mm之间可调整 |

夹芯板厚度 | 30~200mm |

使用聚氨酯发泡机 | 高压发泡机 |

聚氨酯泡沫 - 密度 - 泡沫压力 | PUR/ PIR-硬质泡沫 约40±5kg/ 最大为0.3kg/ |

最大为 0.4kp/ |

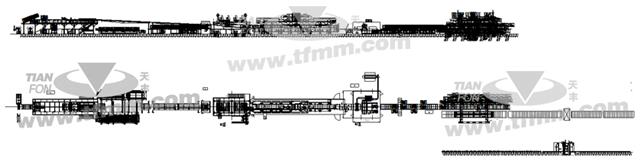

Three, production line arrangement:

Process description:

(upper) open book to guide sent to shear, the paster, and embossing roller wheel molding ↘

Steel heating and coating and laminating machine in foaming, curing, molding, cutting to flip, stacking, finished product packaging

(bottom) open book to guide sent to shear, the paster, ↗ and embossing roller wheel molding

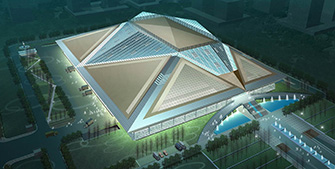

Four, polyurethane board finished product:

E-mail:contact@tianfon.com

Address:China, xinxiang, high-tech development

zone is a new street, number 369-1

-

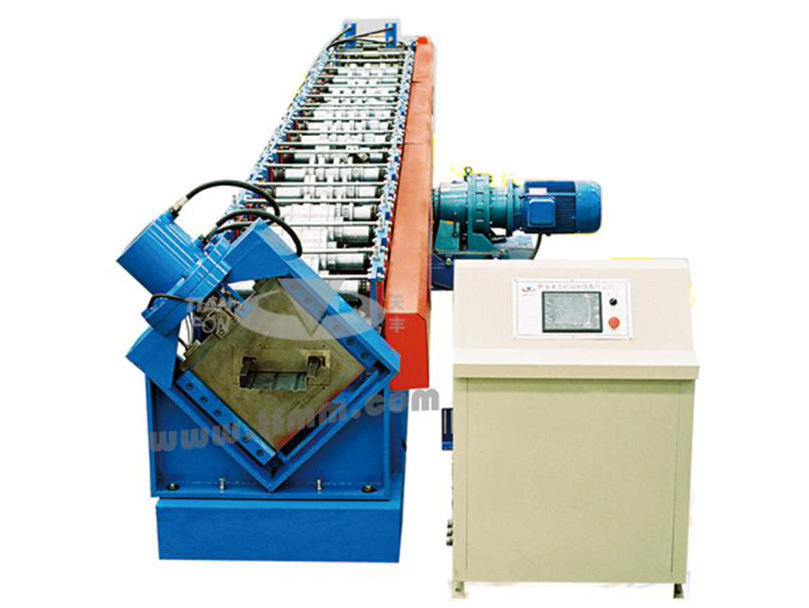

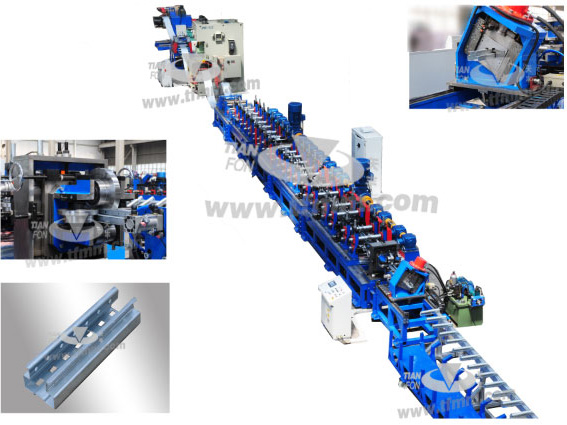

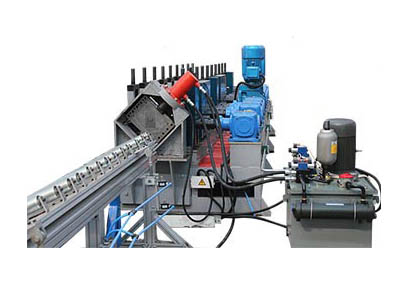

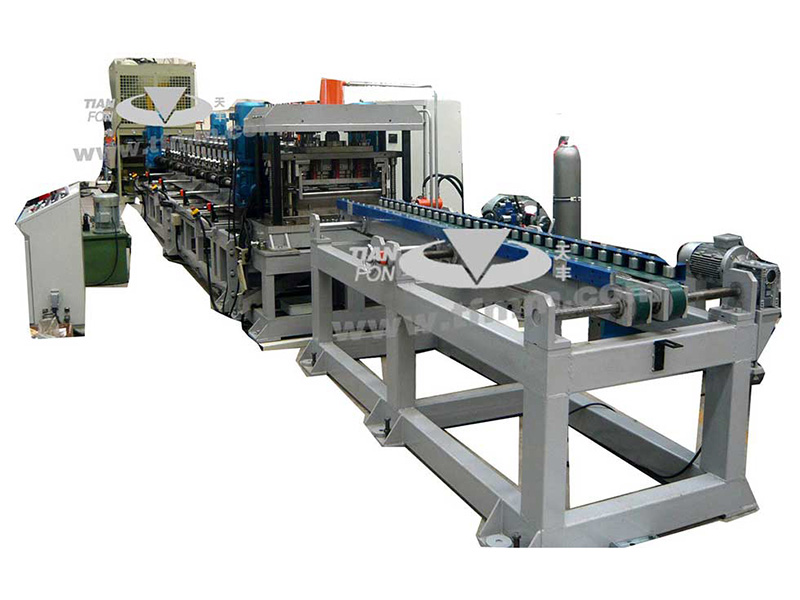

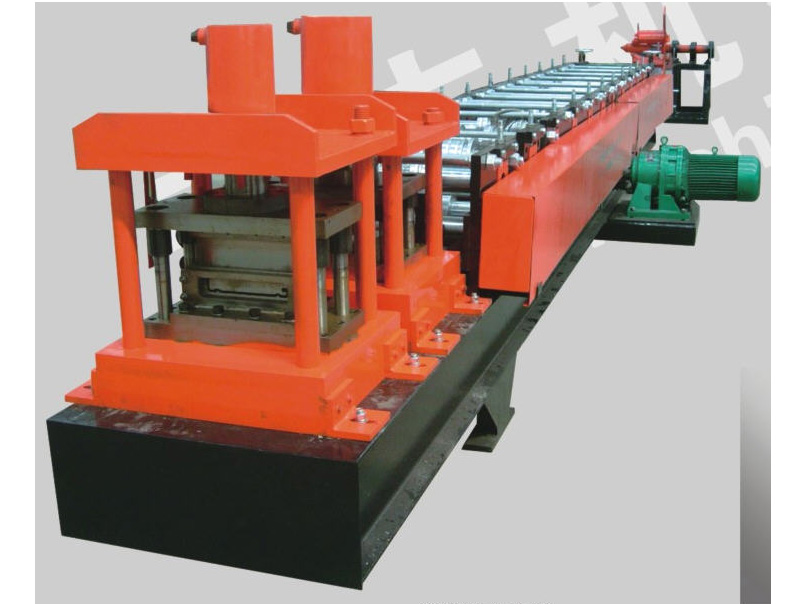

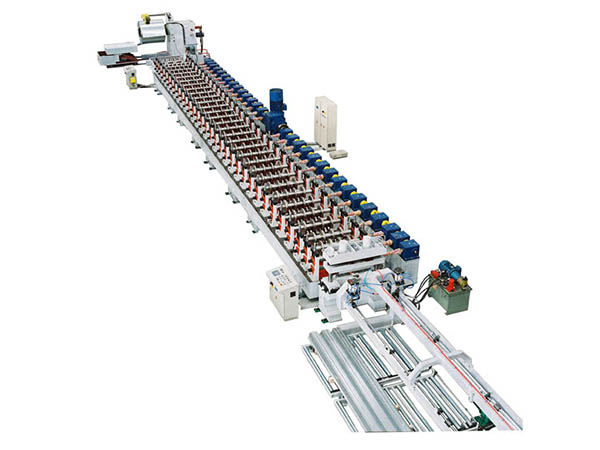

Parking equipment side beam cold bending production line

Parking equipment side beam cold bending production line -

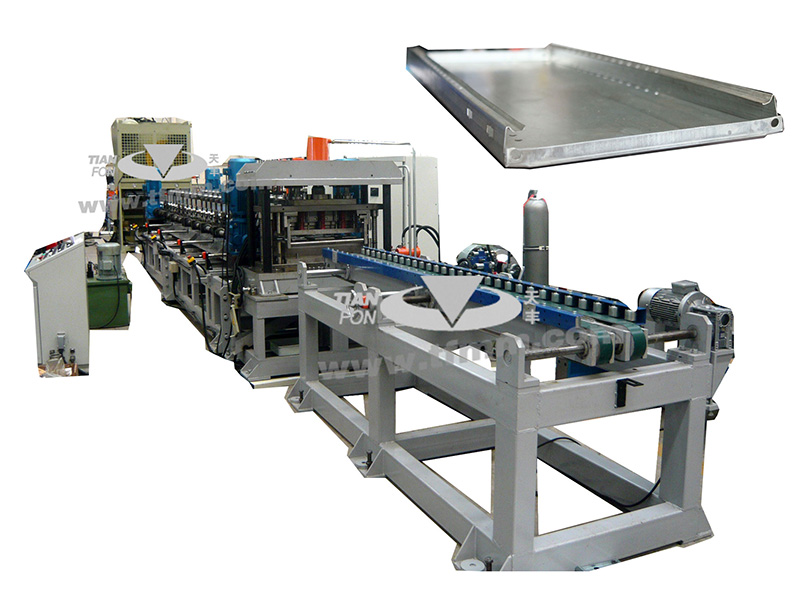

Parking equipment base plate cold bending equipment

Parking equipment base plate cold bending equipment -

Protection plate cold bending equipment

Protection plate cold bending equipment -

Shutter cold bending steel equipment

Shutter cold bending steel equipment -

Cold bending forming equipment for metal door and window frame

Cold bending forming equipment for metal door and window frame -

Metal door plank of cold bending equipment

Metal door plank of cold bending equipment -

Cold formed steel forming production line of solar powered support

Cold formed steel forming production line of solar powered support -

PV stand cold formed steel production line

PV stand cold formed steel production line -

Shelves column profile cold-formed molding equipment

Shelves column profile cold-formed molding equipment -

Box type a series of cold bending production line

Box type a series of cold bending production line -

TF shelves baffle plate production line

TF shelves baffle plate production line -

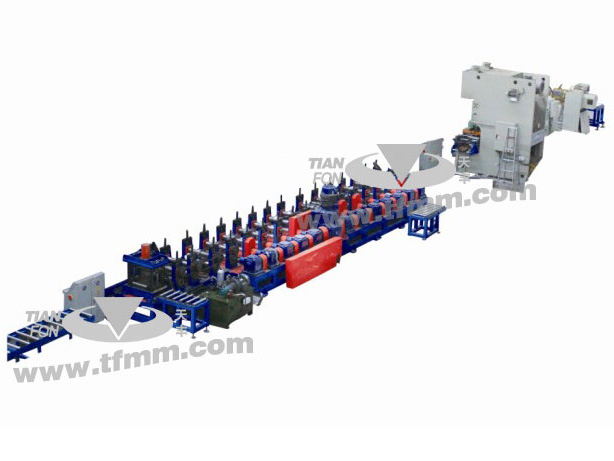

Light rail, subway conductive stainless steel cold bending production line

Light rail, subway conductive stainless steel cold bending production line -

Metal lampshade automatically cold bending production line

Metal lampshade automatically cold bending production line -

The elevator with hollow guide cold bending steel equipment

The elevator with hollow guide cold bending steel equipment -

Electric cabinet supporting pillar of cold bend forming machine

Electric cabinet supporting pillar of cold bend forming machine -

Cold bending forming machine mining W steel belt

Cold bending forming machine mining W steel belt -

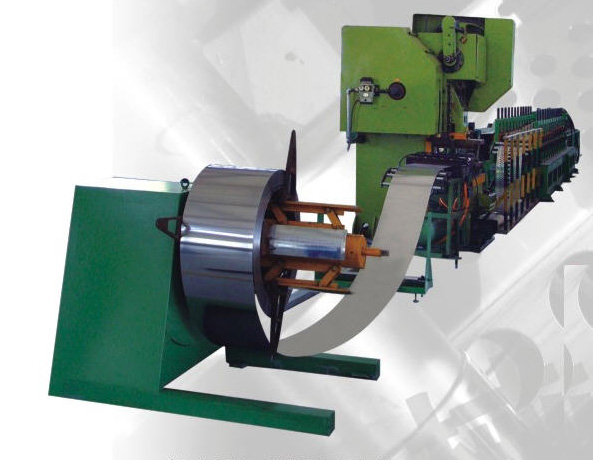

Open book, slitting and winding line

Open book, slitting and winding line -

Uncoiling, leveling, cutting, palletizing production line

Uncoiling, leveling, cutting, palletizing production line -

Double row cold bending production line

Double row cold bending production line -

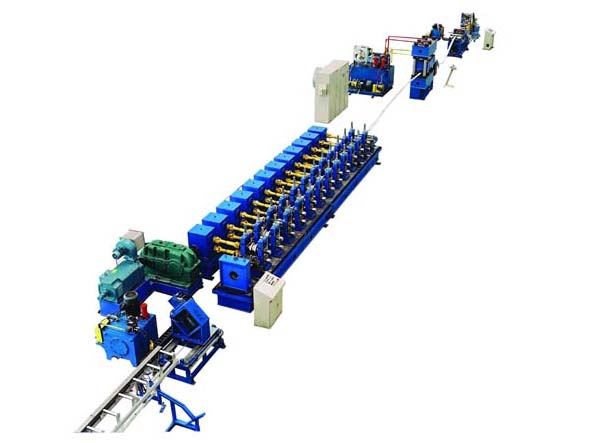

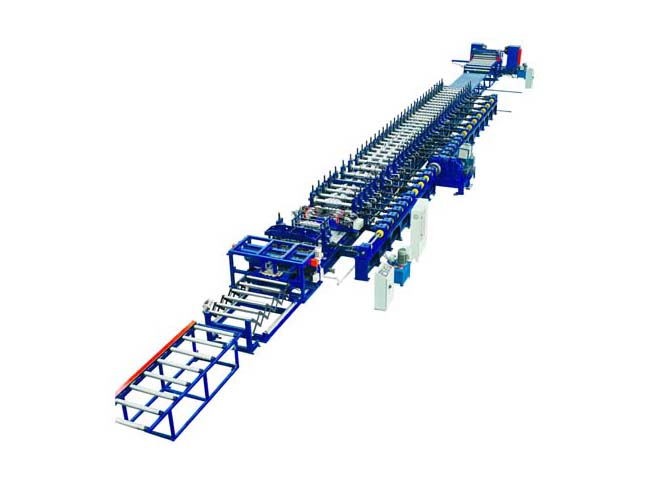

Light steel keel cold bending equipment

Light steel keel cold bending equipment -

Metal packing steel cold bending forming production line

Metal packing steel cold bending forming production line -

Fire dampers cold bending steel molding equipment

Fire dampers cold bending steel molding equipment -

TF crane rail cold-formed molding equipment

TF crane rail cold-formed molding equipment -

TF piling sheet roll forming line

TF piling sheet roll forming line -

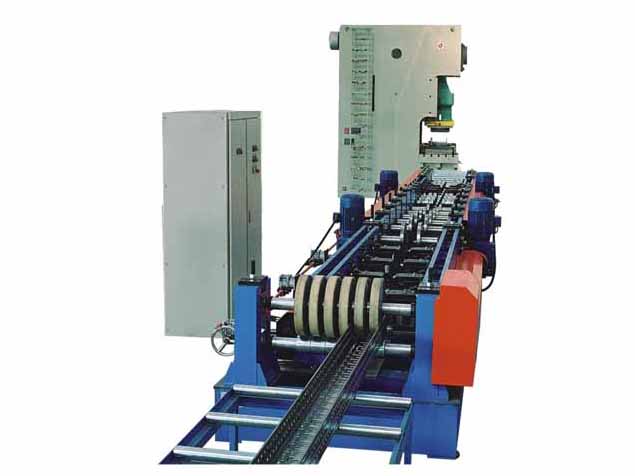

TF30-54 vineyard post automatic punching cold bending forming production line

TF30-54 vineyard post automatic punching cold bending forming production line -

TF sound insulation plate cold bending production line

TF sound insulation plate cold bending production line -

Automotive cover plate, container plate cold bending equipment

Automotive cover plate, container plate cold bending equipment -

The car plate - plate, plate forming production line

The car plate - plate, plate forming production line -

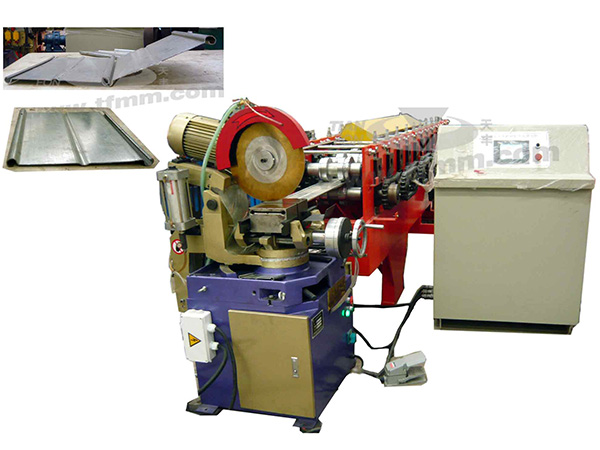

Car plate molding equipment

Car plate molding equipment -

Guide cold bending production line

Guide cold bending production line -

Days beauty FengGe polyurethane (PU) sandwich panel continuous production line

Days beauty FengGe polyurethane (PU) sandwich panel continuous production line -

Day FengGe energy-saving fire phenolic sheet continuous production line

Day FengGe energy-saving fire phenolic sheet continuous production line -

Day FengGe energy-saving fire-resistant phenolic board, polyurethane board

Day FengGe energy-saving fire-resistant phenolic board, polyurethane board -

Tray type cable tray equipment

Tray type cable tray equipment -

Cascade type cable tray equipment

Cascade type cable tray equipment -

Cable tray busway shell cold bending production line

Cable tray busway shell cold bending production line -

Groove type cable tray equipment

Groove type cable tray equipment -

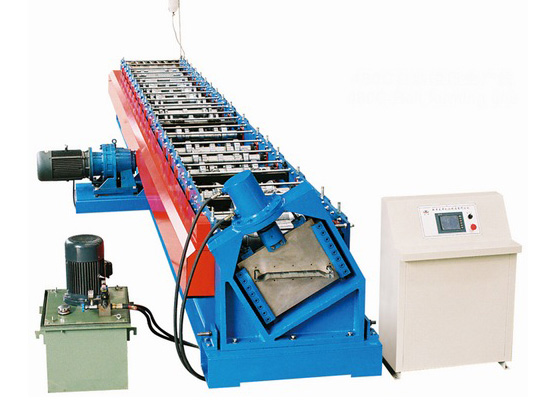

Dust suppression plate production line

Dust suppression plate production line -

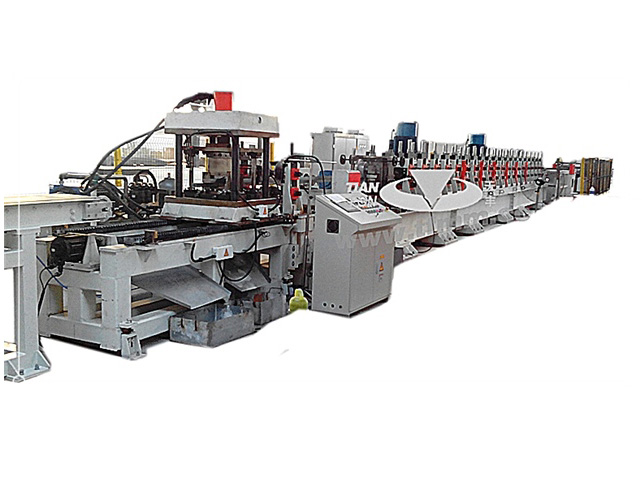

ZT24 anode plate forming machine

ZT24 anode plate forming machine -

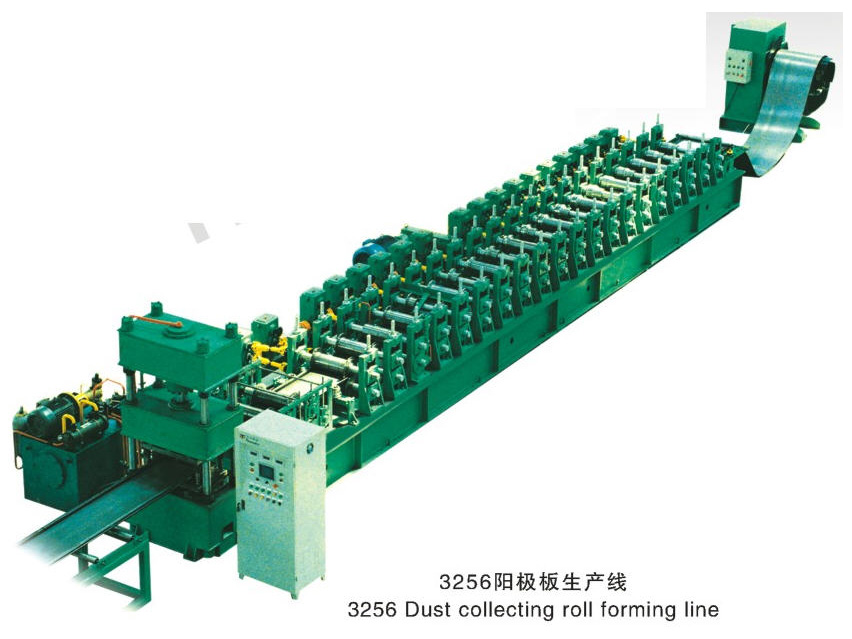

3256 anode plate production line

3256 anode plate production line -

480 anode plate forming machine

480 anode plate forming machine -

Space edge rib cold bending production line

Space edge rib cold bending production line -

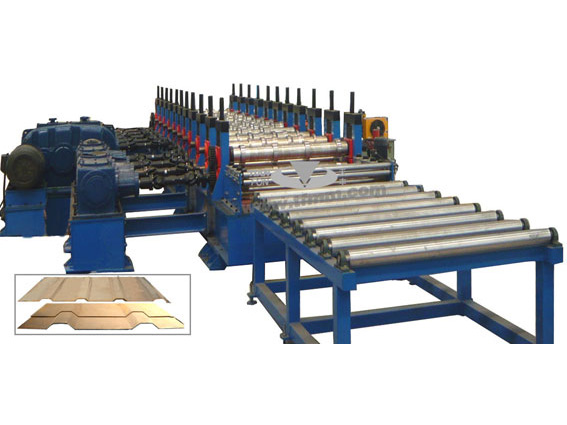

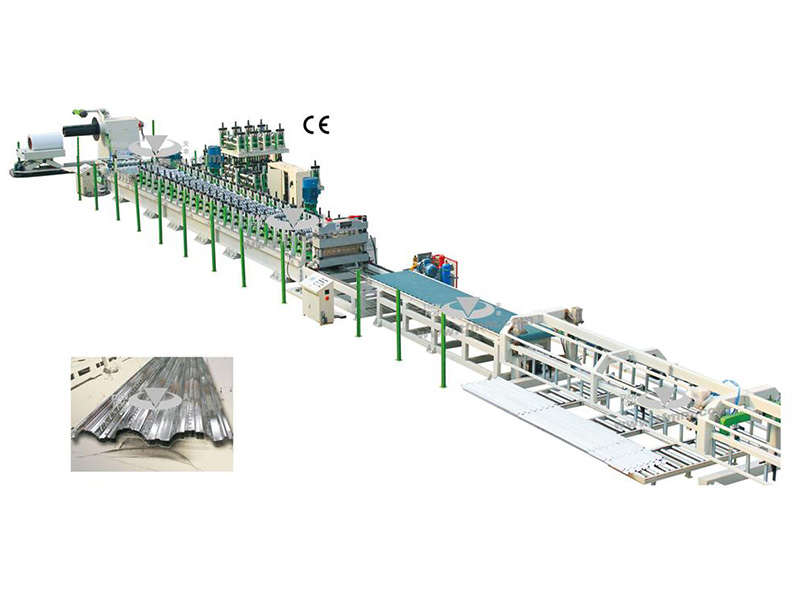

Wall panels, roof plate cold bending forming production line

Wall panels, roof plate cold bending forming production line -

LouCheng plate cold bending production line

LouCheng plate cold bending production line -

Glazed tile cold bending production line

Glazed tile cold bending production line -

Container house profile cold bending production line

Container house profile cold bending production line -

TF buildings, storage use C60-250 profile punching steel springboard cold bending molding line

TF buildings, storage use C60-250 profile punching steel springboard cold bending molding line -

TF steel structure of fully automatic CNC high speed cold bending production line

TF steel structure of fully automatic CNC high speed cold bending production line -

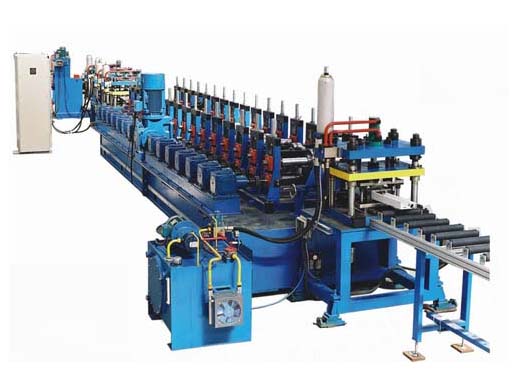

C/Z purlin roll forming machine

C/Z purlin roll forming machine