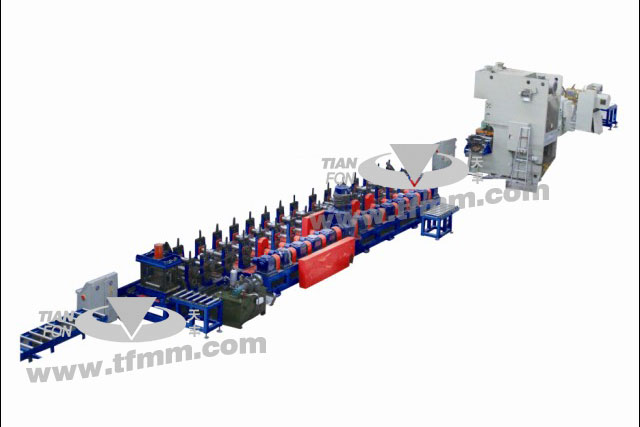

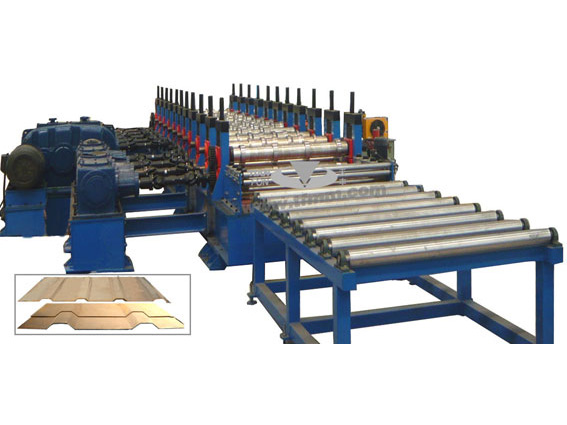

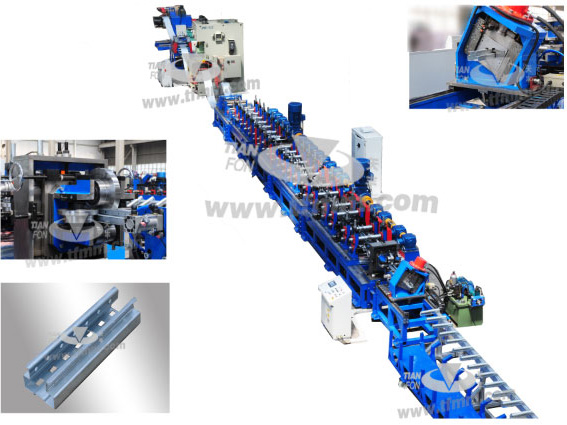

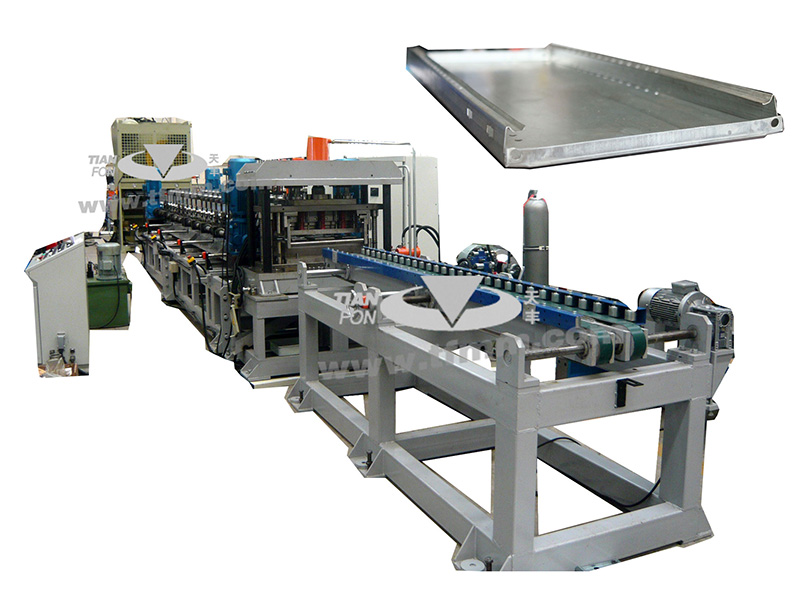

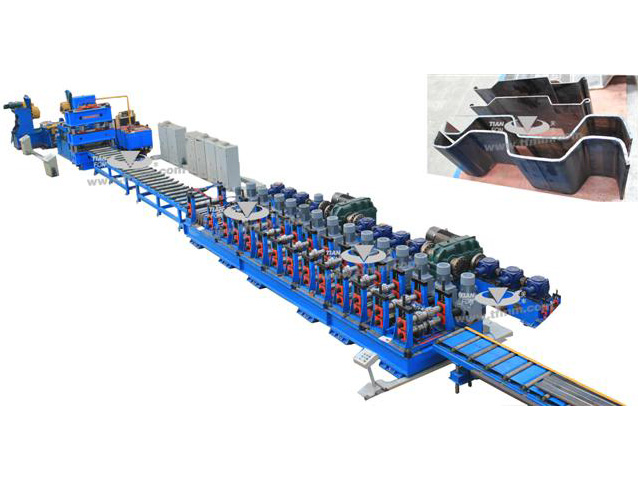

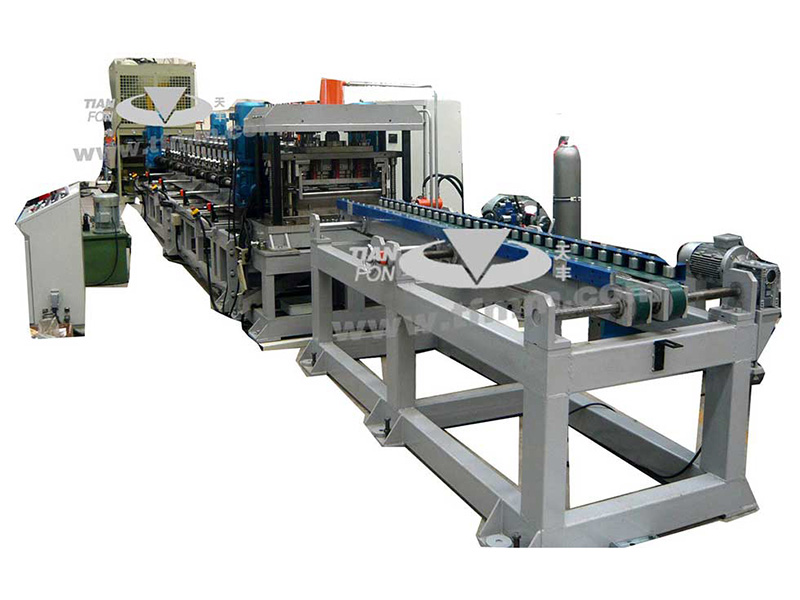

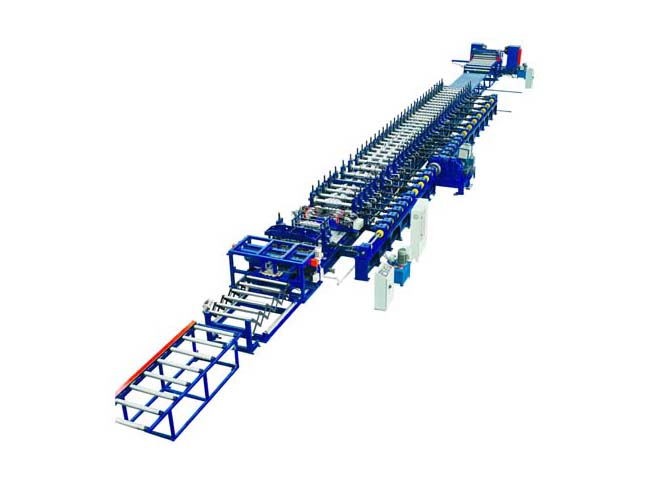

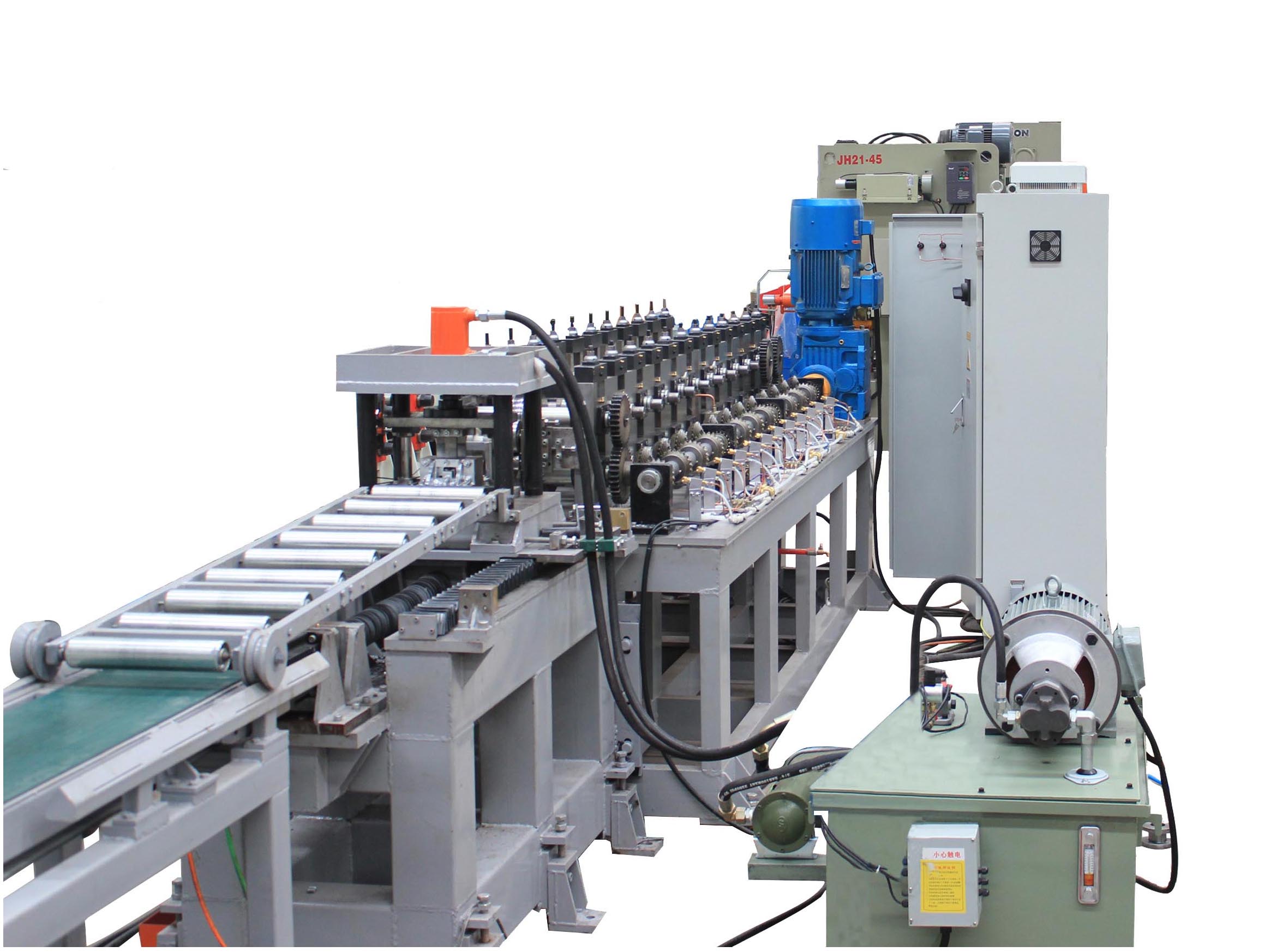

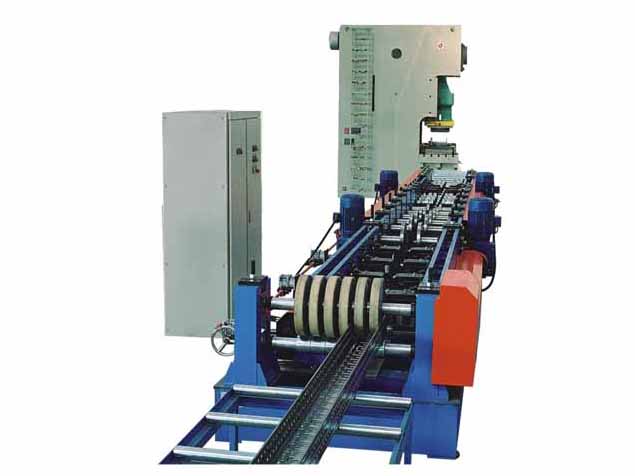

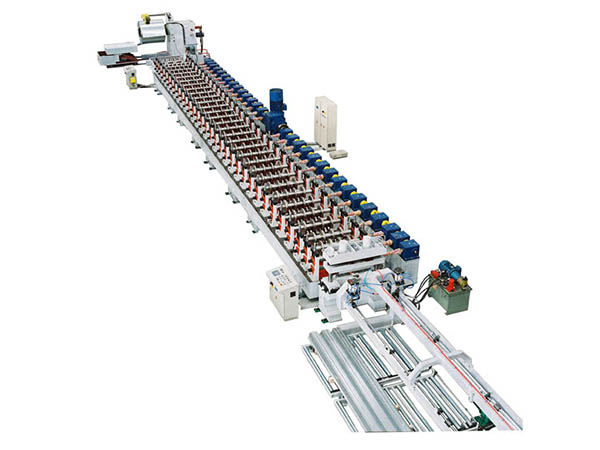

1, building, storage and use C60-250 profile punch cold-formed steel plank production line main technical parameters:

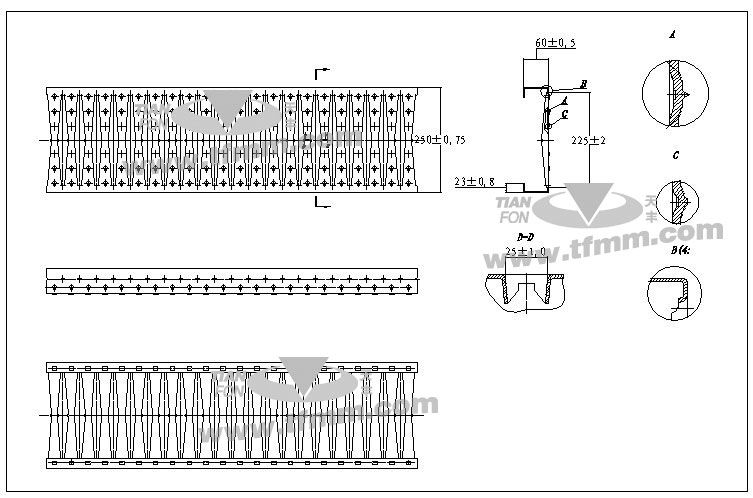

1) thickness: 2.0 mm

2) material width: about 406 mm

3) material: Q235

4) yield strength: 235 mpa or less

5) forming time: about 16

6) forming roll material: GCr15, hardness HRC58-62, surface hard chromium plating.

7) production speed: about 5-6 m/min

8) tolerance of size: 300 mm from end within the mouth of tolerance + / - 2 mm

9) electricity source, three-phase ac power supply: 380 v (+ / - 10%), 50 hz

10) temperature: - 10 ℃ to 40 ℃, relative humidity: 90% or less (25 ℃) without coagulate frost

11) area: about 31 m * 3.5 m

2, building, storage use C60-250 profile punching steel springboard of cold bending production line process flow and equipment:

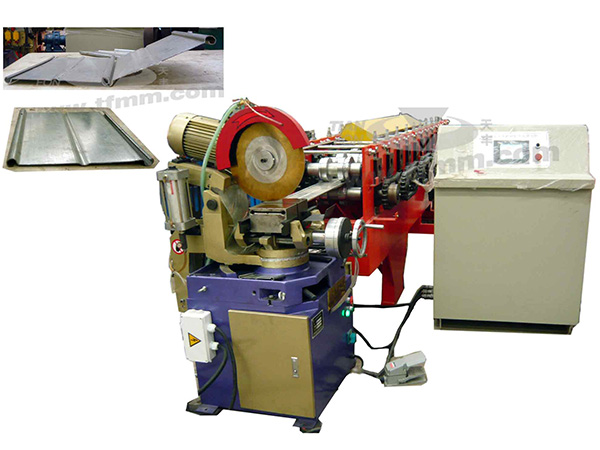

Open book - leveling to servo feeding, punching and flanging forming - tracking cut - out

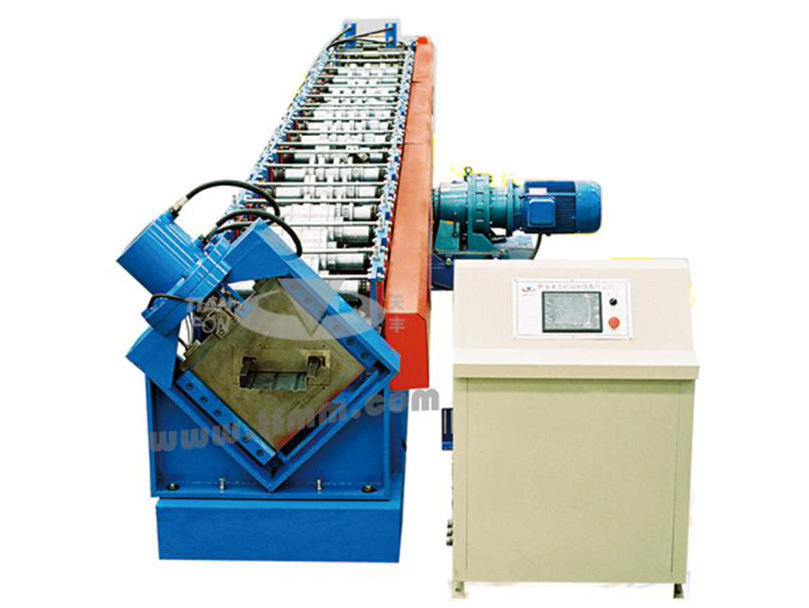

3, building, storage use C60-250 profile steel springboard punching cold bending production line configuration:

A) a decoiler

B) a leveling machine

C) servo feed one

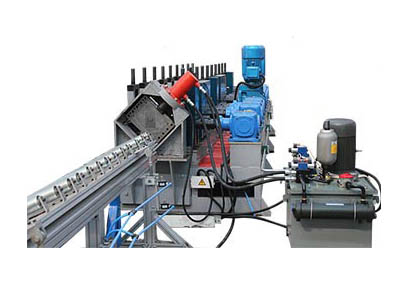

D) punching molding press

E) machine (including the roll)

F) tracking cutting machine

G) a set of discharge

H) a set of hydraulic system

I) a set of electric control system

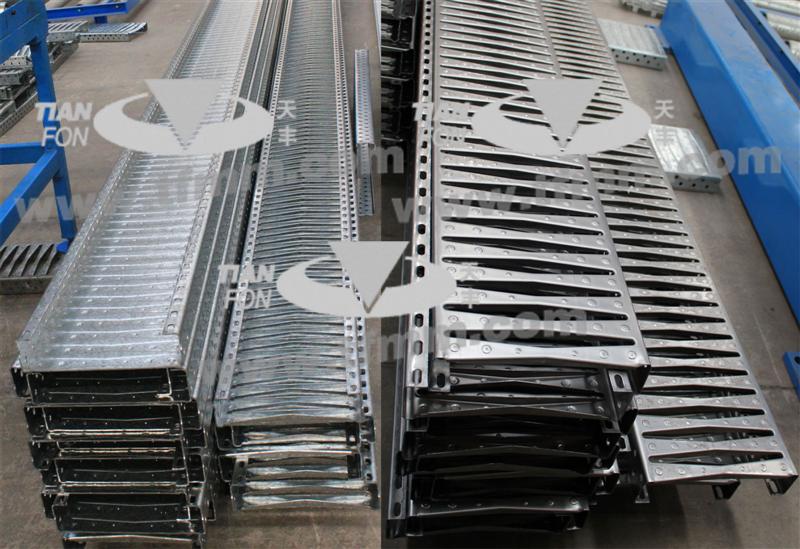

Steel springboard board USES include:

1, the construction steel springboard

2, storage shelves or heavy warehousing logistics center

3, helipad

4, boat and boat ramp extended

5, farms

6, warehouse floor

7, mobile computer room

8, rv, or storage area

9, heavy equipment, supplies or runway storage platform.

E-mail:contact@tianfon.com

Address:China, xinxiang, high-tech development

zone is a new street, number 369-1

-

Parking equipment side beam cold bending production line

Parking equipment side beam cold bending production line -

Parking equipment base plate cold bending equipment

Parking equipment base plate cold bending equipment -

Protection plate cold bending equipment

Protection plate cold bending equipment -

Shutter cold bending steel equipment

Shutter cold bending steel equipment -

Cold bending forming equipment for metal door and window frame

Cold bending forming equipment for metal door and window frame -

Metal door plank of cold bending equipment

Metal door plank of cold bending equipment -

Cold formed steel forming production line of solar powered support

Cold formed steel forming production line of solar powered support -

PV stand cold formed steel production line

PV stand cold formed steel production line -

Shelves column profile cold-formed molding equipment

Shelves column profile cold-formed molding equipment -

Box type a series of cold bending production line

Box type a series of cold bending production line -

TF shelves baffle plate production line

TF shelves baffle plate production line -

Light rail, subway conductive stainless steel cold bending production line

Light rail, subway conductive stainless steel cold bending production line -

Metal lampshade automatically cold bending production line

Metal lampshade automatically cold bending production line -

The elevator with hollow guide cold bending steel equipment

The elevator with hollow guide cold bending steel equipment -

Electric cabinet supporting pillar of cold bend forming machine

Electric cabinet supporting pillar of cold bend forming machine -

Cold bending forming machine mining W steel belt

Cold bending forming machine mining W steel belt -

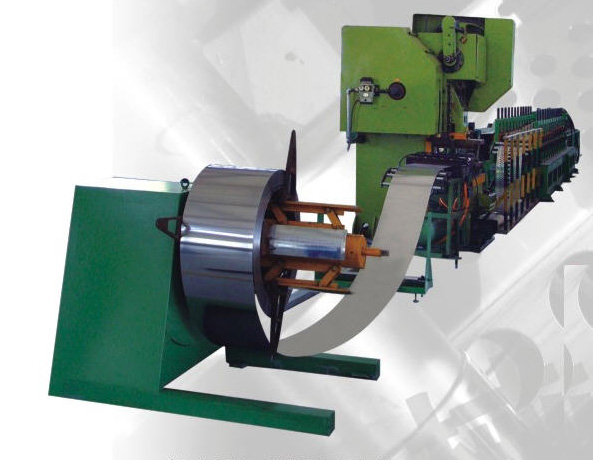

Open book, slitting and winding line

Open book, slitting and winding line -

Uncoiling, leveling, cutting, palletizing production line

Uncoiling, leveling, cutting, palletizing production line -

Double row cold bending production line

Double row cold bending production line -

Light steel keel cold bending equipment

Light steel keel cold bending equipment -

Metal packing steel cold bending forming production line

Metal packing steel cold bending forming production line -

Fire dampers cold bending steel molding equipment

Fire dampers cold bending steel molding equipment -

TF crane rail cold-formed molding equipment

TF crane rail cold-formed molding equipment -

TF piling sheet roll forming line

TF piling sheet roll forming line -

TF30-54 vineyard post automatic punching cold bending forming production line

TF30-54 vineyard post automatic punching cold bending forming production line -

TF sound insulation plate cold bending production line

TF sound insulation plate cold bending production line -

Automotive cover plate, container plate cold bending equipment

Automotive cover plate, container plate cold bending equipment -

The car plate - plate, plate forming production line

The car plate - plate, plate forming production line -

Car plate molding equipment

Car plate molding equipment -

Guide cold bending production line

Guide cold bending production line -

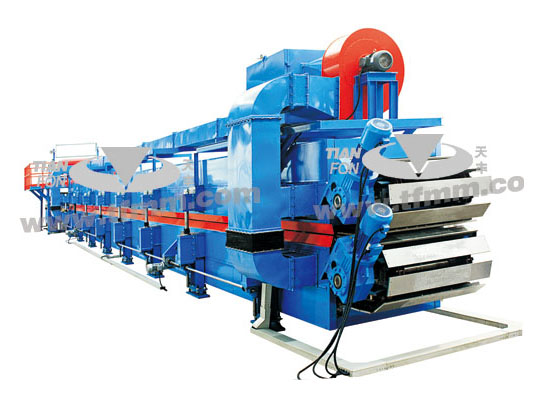

Days beauty FengGe polyurethane (PU) sandwich panel continuous production line

Days beauty FengGe polyurethane (PU) sandwich panel continuous production line -

Day FengGe energy-saving fire phenolic sheet continuous production line

Day FengGe energy-saving fire phenolic sheet continuous production line -

Day FengGe energy-saving fire-resistant phenolic board, polyurethane board

Day FengGe energy-saving fire-resistant phenolic board, polyurethane board -

Tray type cable tray equipment

Tray type cable tray equipment -

Cascade type cable tray equipment

Cascade type cable tray equipment -

Cable tray busway shell cold bending production line

Cable tray busway shell cold bending production line -

Groove type cable tray equipment

Groove type cable tray equipment -

Dust suppression plate production line

Dust suppression plate production line -

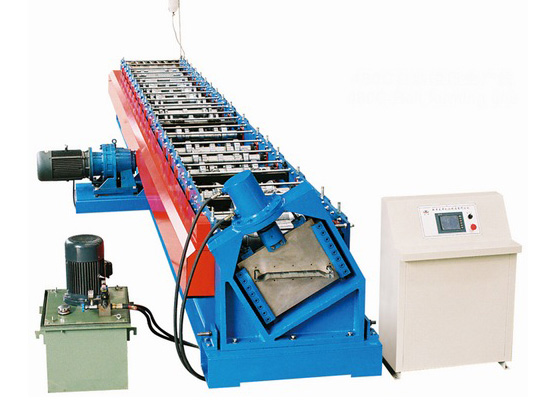

ZT24 anode plate forming machine

ZT24 anode plate forming machine -

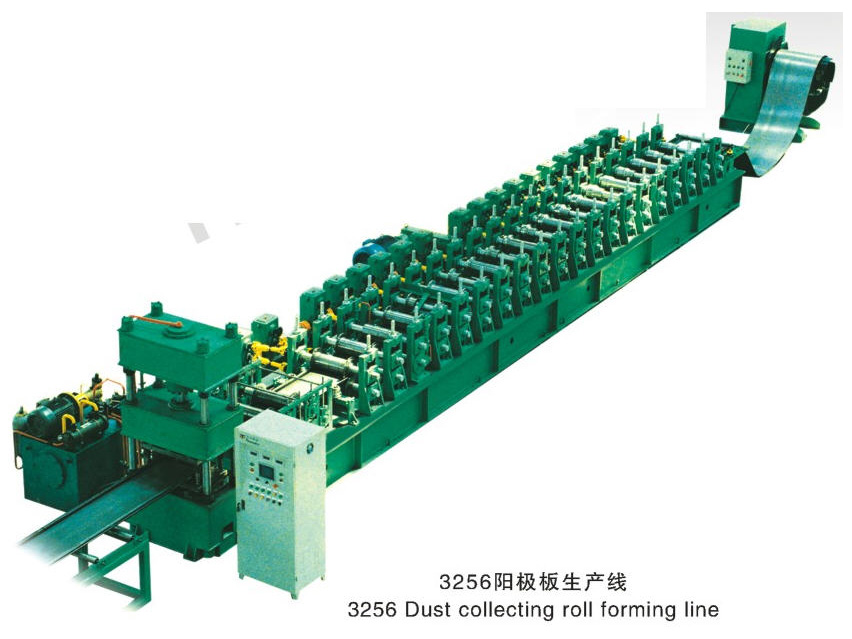

3256 anode plate production line

3256 anode plate production line -

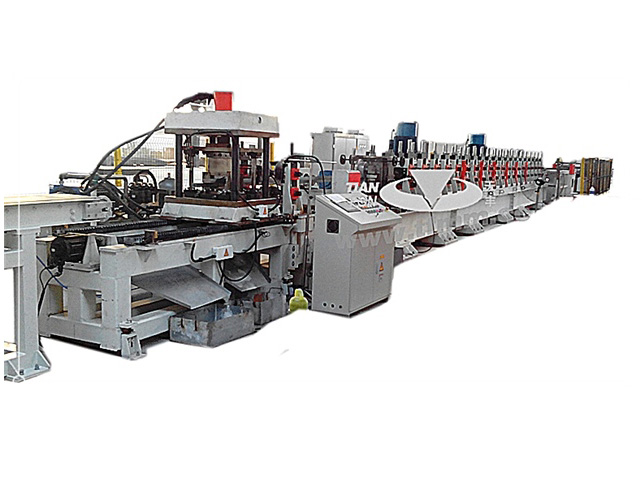

480 anode plate forming machine

480 anode plate forming machine -

Space edge rib cold bending production line

Space edge rib cold bending production line -

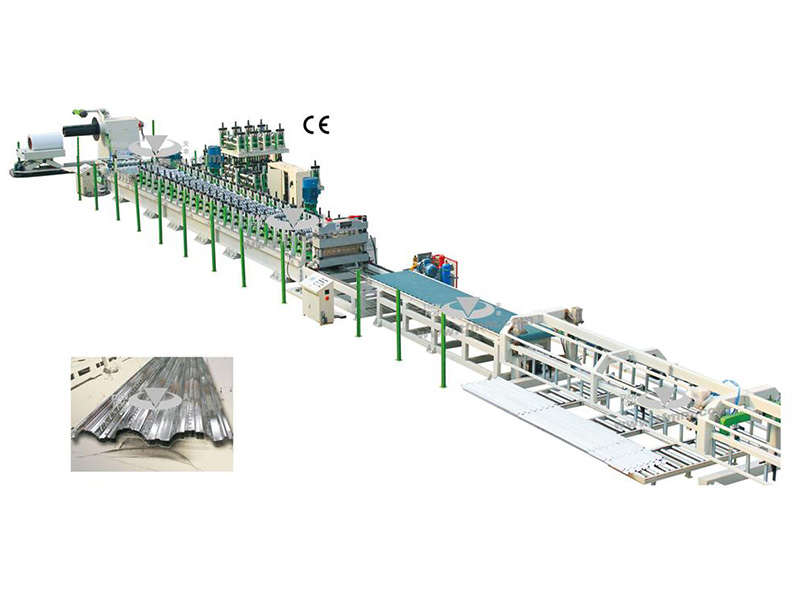

Wall panels, roof plate cold bending forming production line

Wall panels, roof plate cold bending forming production line -

LouCheng plate cold bending production line

LouCheng plate cold bending production line -

Glazed tile cold bending production line

Glazed tile cold bending production line -

Container house profile cold bending production line

Container house profile cold bending production line -

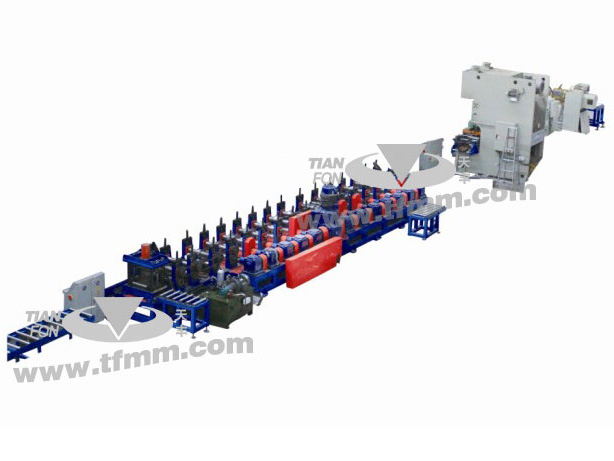

TF buildings, storage use C60-250 profile punching steel springboard cold bending molding line

TF buildings, storage use C60-250 profile punching steel springboard cold bending molding line -

TF steel structure of fully automatic CNC high speed cold bending production line

TF steel structure of fully automatic CNC high speed cold bending production line -

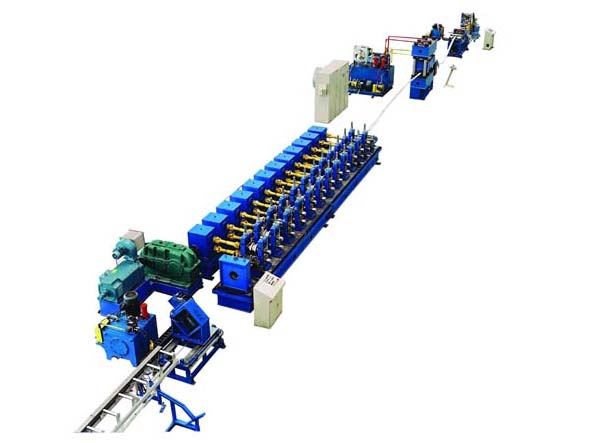

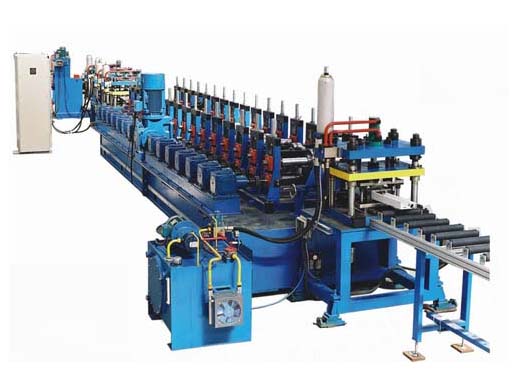

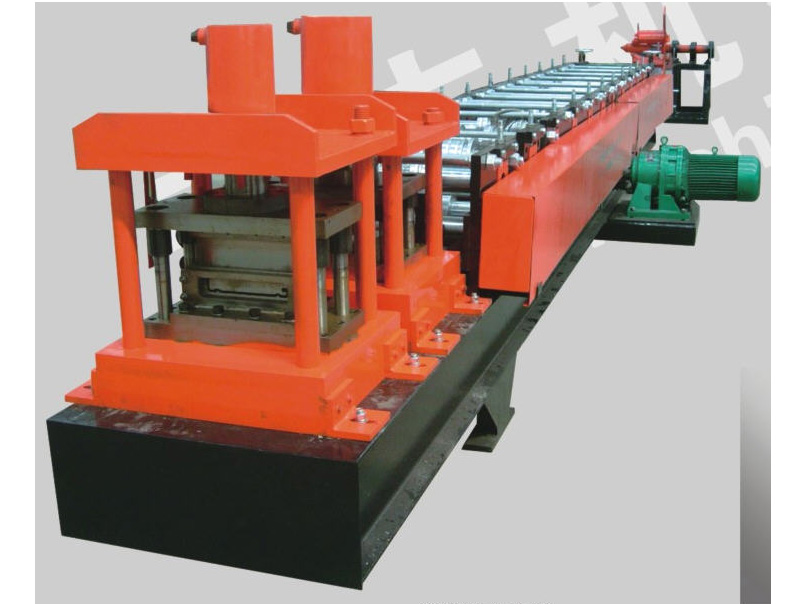

C/Z purlin roll forming machine

C/Z purlin roll forming machine