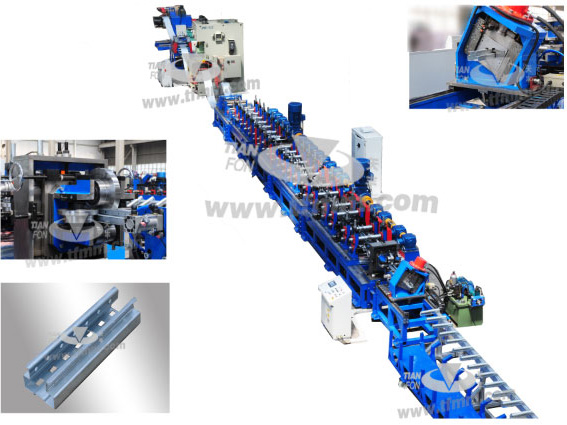

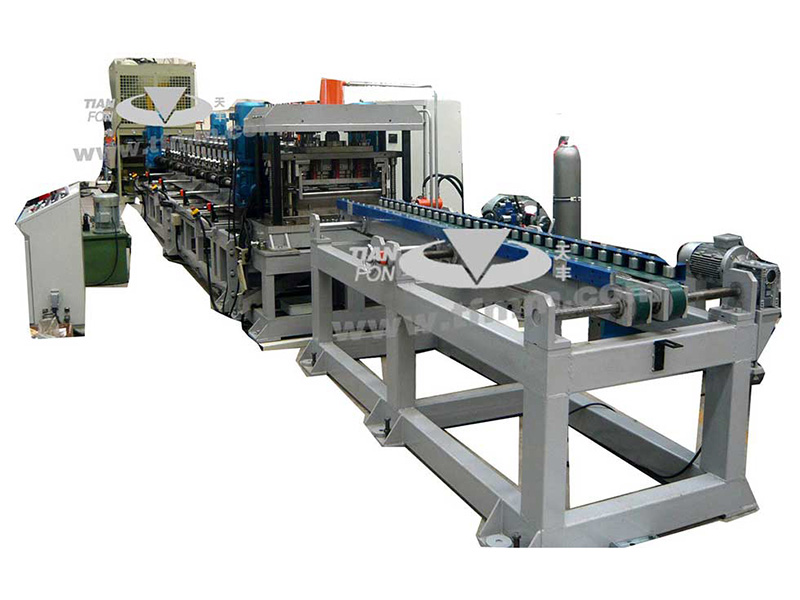

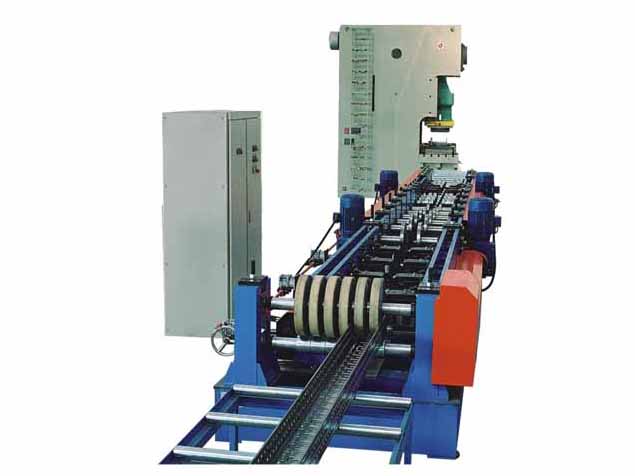

Tray type cable tray equipment consists of decoiler, leveling machine, feeder, punching machine, stamping die, punching and embossing, cutting), discharge frame, electric control system of production line speed: 3-3.5 m/min.

A tray type cable tray equipment main technical parameters

According to production needs A rolling width is 120 mm or less § 960 mm or less A variety of specifications of the cable tray

B material requirements: Q235 manufacture

C: material thickness 0.8 2.0 mm

D rolling specifications:

50 mm * 100 mm * 75 mm * 75 mm

50 mm * 200 mm * 200 mm * 75 mm * 150 mm

Second, the production of cable tray products specifications

The Size specification Model Size

Height 50/100/150

Width 100/200/300/400/300/400

E-mail:contact@tianfon.com

Address:China, xinxiang, high-tech development

zone is a new street, number 369-1

-

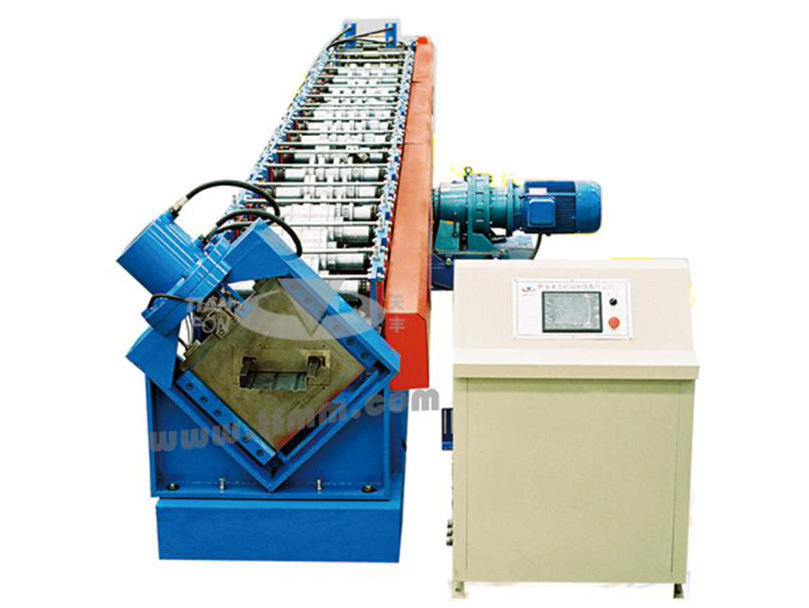

Parking equipment side beam cold bending production line

Parking equipment side beam cold bending production line -

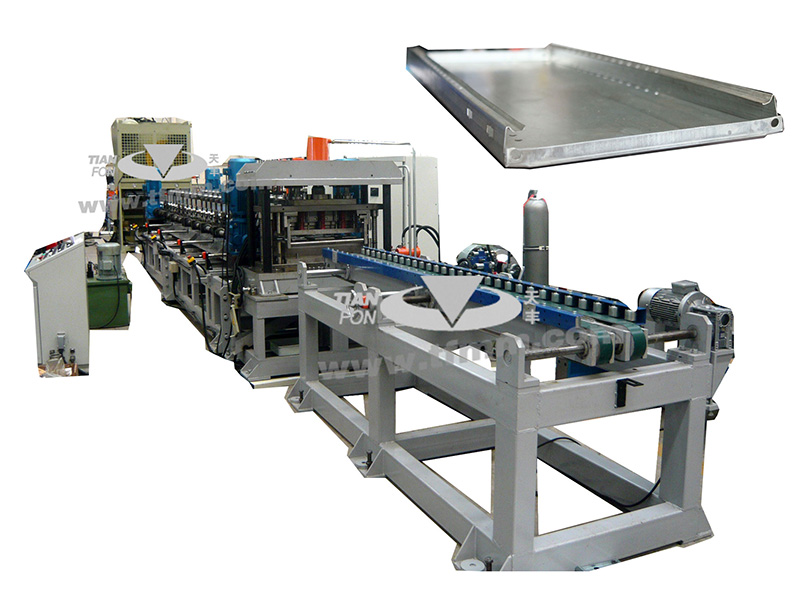

Parking equipment base plate cold bending equipment

Parking equipment base plate cold bending equipment -

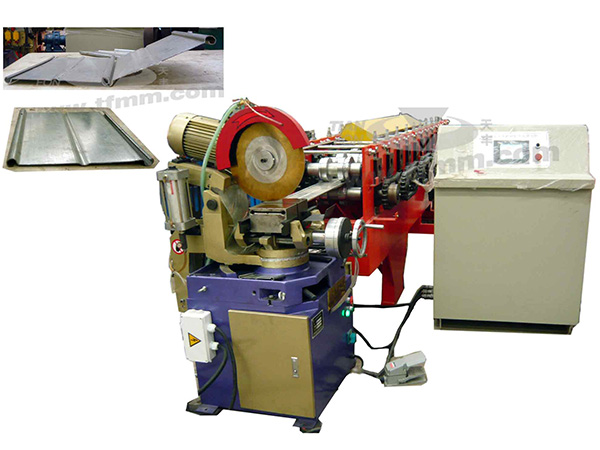

Protection plate cold bending equipment

Protection plate cold bending equipment -

Shutter cold bending steel equipment

Shutter cold bending steel equipment -

Cold bending forming equipment for metal door and window frame

Cold bending forming equipment for metal door and window frame -

Metal door plank of cold bending equipment

Metal door plank of cold bending equipment -

Cold formed steel forming production line of solar powered support

Cold formed steel forming production line of solar powered support -

PV stand cold formed steel production line

PV stand cold formed steel production line -

Shelves column profile cold-formed molding equipment

Shelves column profile cold-formed molding equipment -

Box type a series of cold bending production line

Box type a series of cold bending production line -

TF shelves baffle plate production line

TF shelves baffle plate production line -

Light rail, subway conductive stainless steel cold bending production line

Light rail, subway conductive stainless steel cold bending production line -

Metal lampshade automatically cold bending production line

Metal lampshade automatically cold bending production line -

The elevator with hollow guide cold bending steel equipment

The elevator with hollow guide cold bending steel equipment -

Electric cabinet supporting pillar of cold bend forming machine

Electric cabinet supporting pillar of cold bend forming machine -

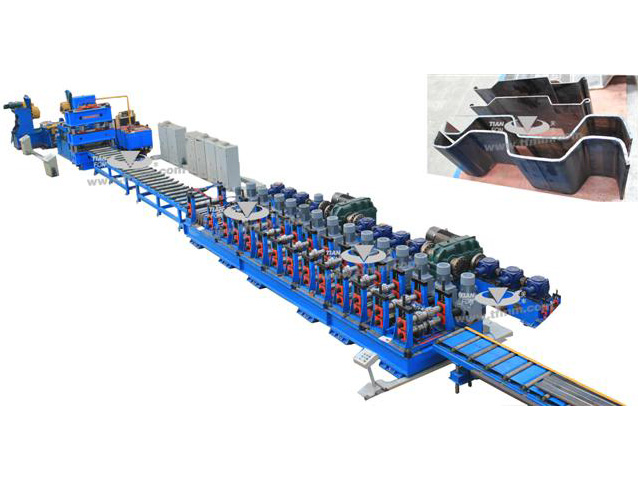

Cold bending forming machine mining W steel belt

Cold bending forming machine mining W steel belt -

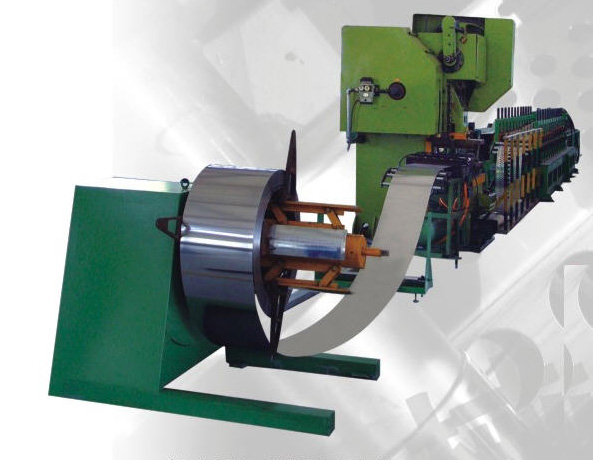

Open book, slitting and winding line

Open book, slitting and winding line -

Uncoiling, leveling, cutting, palletizing production line

Uncoiling, leveling, cutting, palletizing production line -

Double row cold bending production line

Double row cold bending production line -

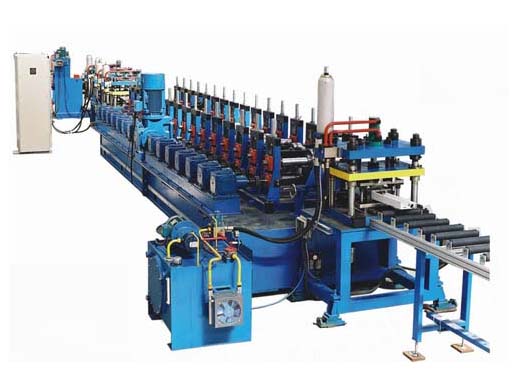

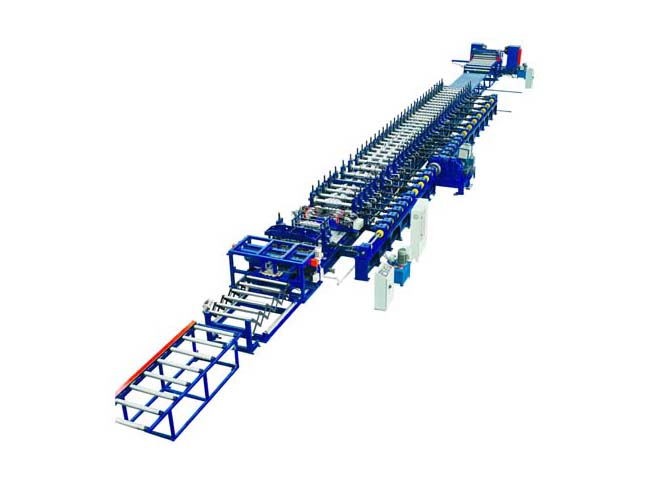

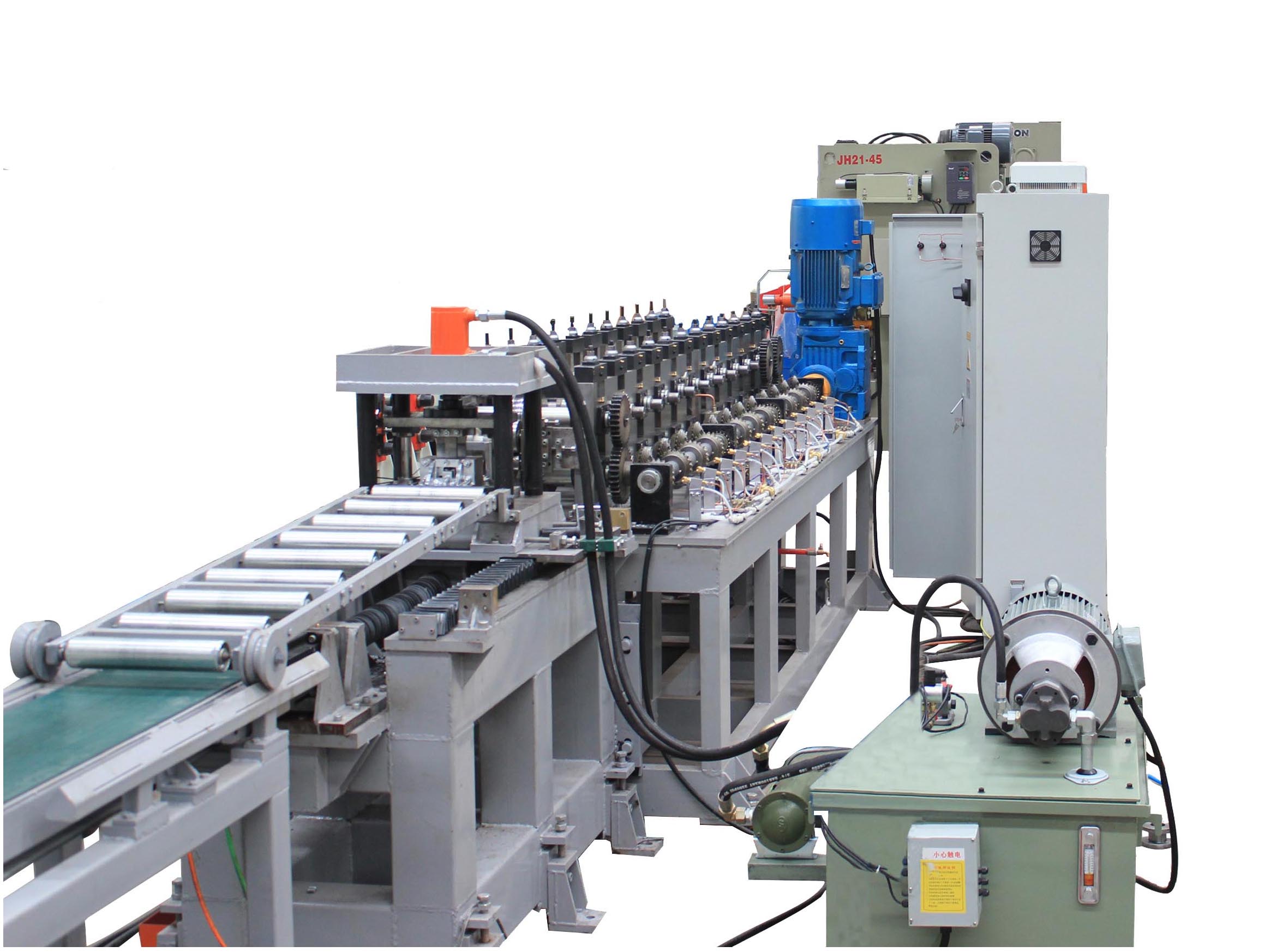

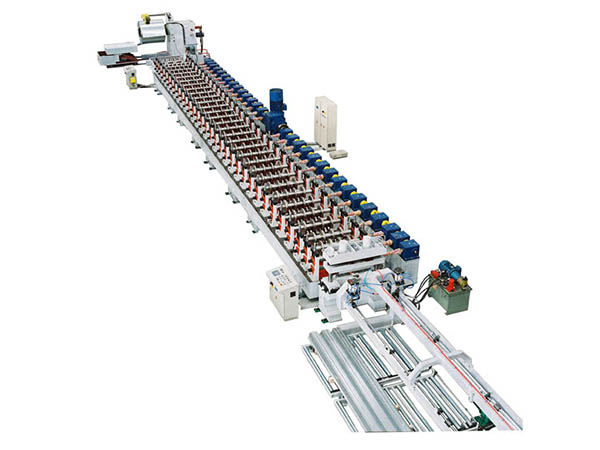

Light steel keel cold bending equipment

Light steel keel cold bending equipment -

Metal packing steel cold bending forming production line

Metal packing steel cold bending forming production line -

Fire dampers cold bending steel molding equipment

Fire dampers cold bending steel molding equipment -

TF crane rail cold-formed molding equipment

TF crane rail cold-formed molding equipment -

TF piling sheet roll forming line

TF piling sheet roll forming line -

TF30-54 vineyard post automatic punching cold bending forming production line

TF30-54 vineyard post automatic punching cold bending forming production line -

TF sound insulation plate cold bending production line

TF sound insulation plate cold bending production line -

Automotive cover plate, container plate cold bending equipment

Automotive cover plate, container plate cold bending equipment -

The car plate - plate, plate forming production line

The car plate - plate, plate forming production line -

Car plate molding equipment

Car plate molding equipment -

Guide cold bending production line

Guide cold bending production line -

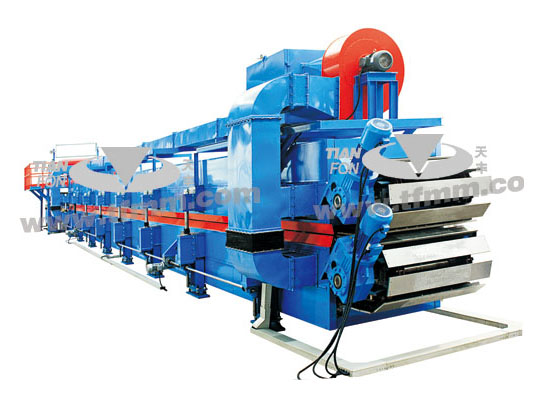

Days beauty FengGe polyurethane (PU) sandwich panel continuous production line

Days beauty FengGe polyurethane (PU) sandwich panel continuous production line -

Day FengGe energy-saving fire phenolic sheet continuous production line

Day FengGe energy-saving fire phenolic sheet continuous production line -

Day FengGe energy-saving fire-resistant phenolic board, polyurethane board

Day FengGe energy-saving fire-resistant phenolic board, polyurethane board -

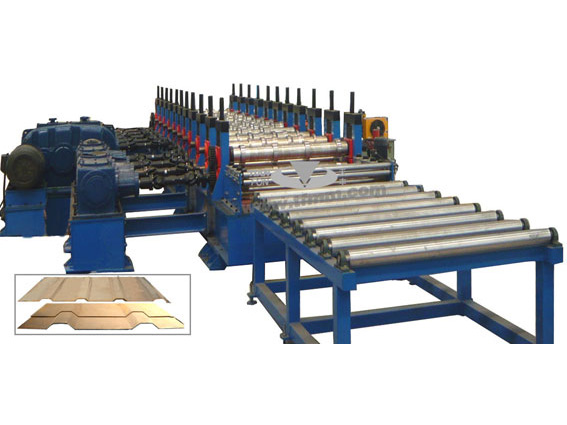

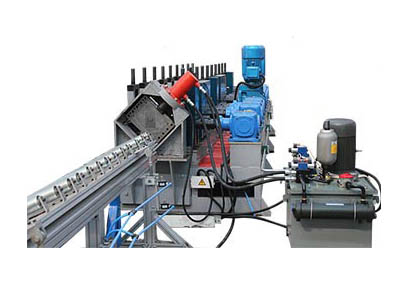

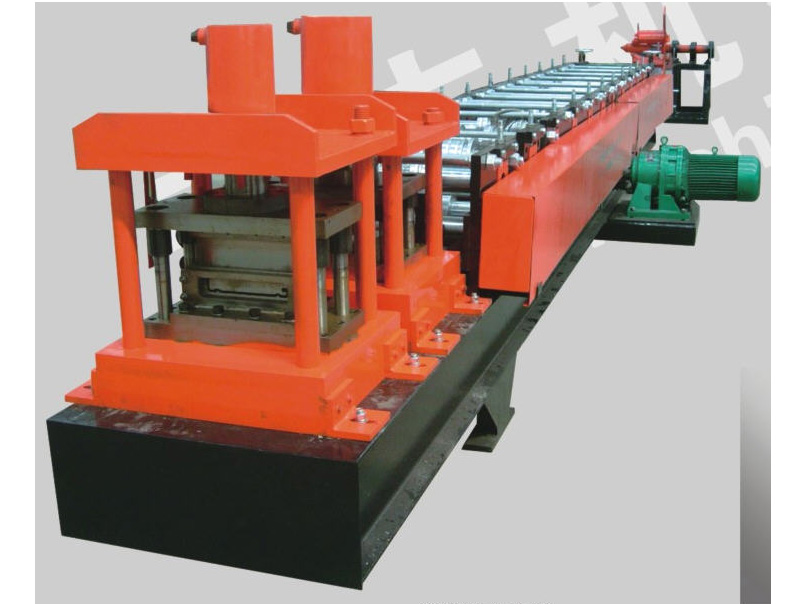

Tray type cable tray equipment

Tray type cable tray equipment -

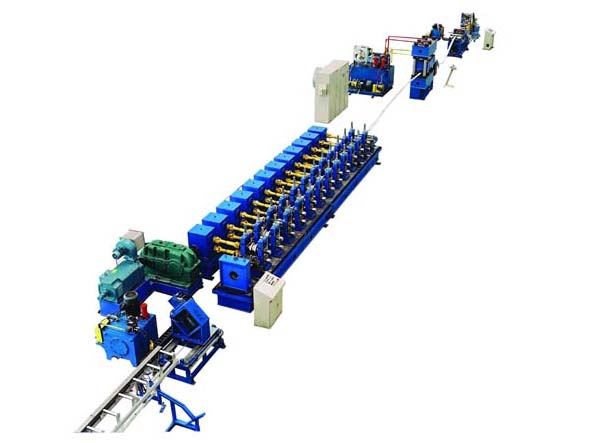

Cascade type cable tray equipment

Cascade type cable tray equipment -

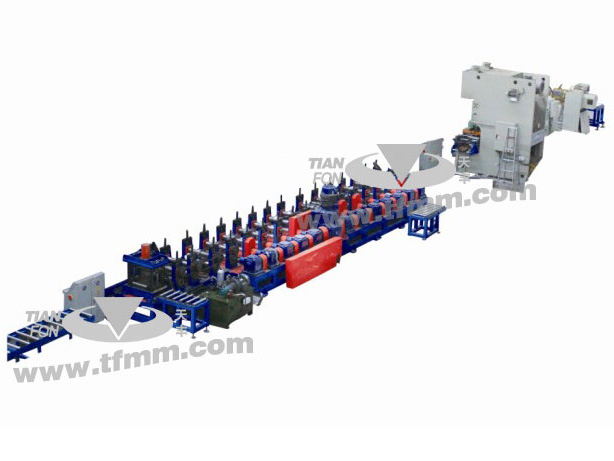

Cable tray busway shell cold bending production line

Cable tray busway shell cold bending production line -

Groove type cable tray equipment

Groove type cable tray equipment -

Dust suppression plate production line

Dust suppression plate production line -

ZT24 anode plate forming machine

ZT24 anode plate forming machine -

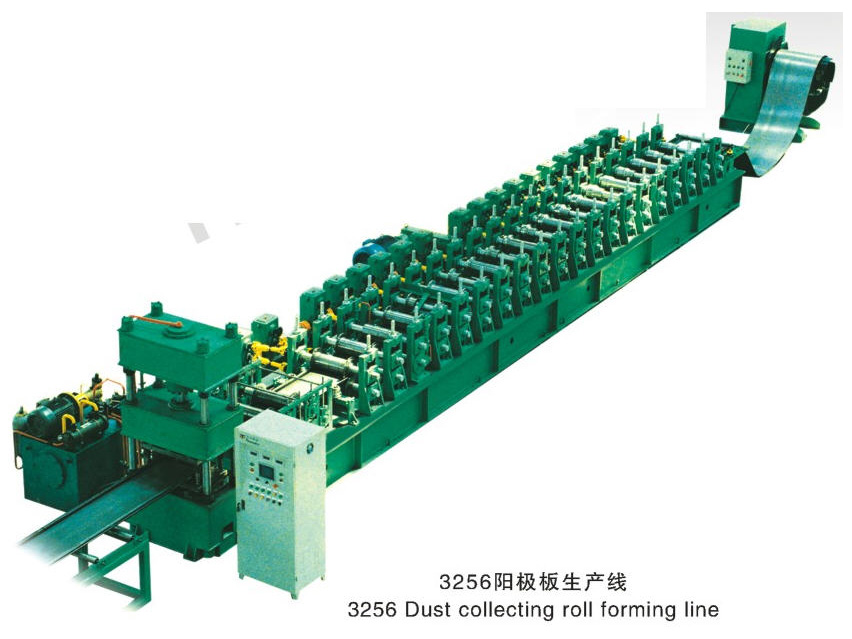

3256 anode plate production line

3256 anode plate production line -

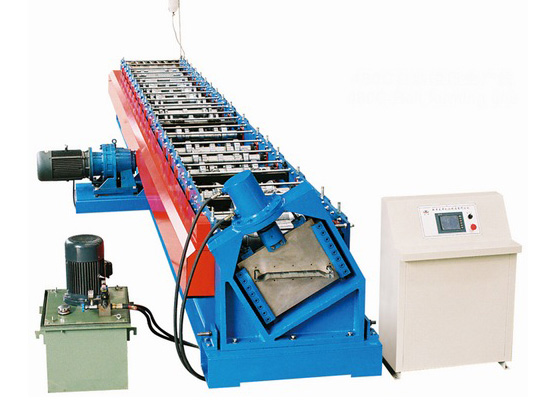

480 anode plate forming machine

480 anode plate forming machine -

Space edge rib cold bending production line

Space edge rib cold bending production line -

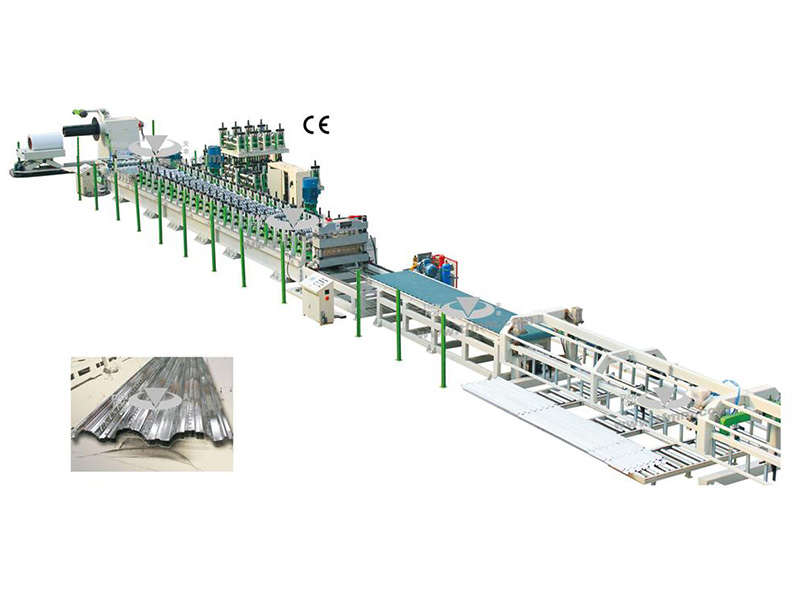

Wall panels, roof plate cold bending forming production line

Wall panels, roof plate cold bending forming production line -

LouCheng plate cold bending production line

LouCheng plate cold bending production line -

Glazed tile cold bending production line

Glazed tile cold bending production line -

Container house profile cold bending production line

Container house profile cold bending production line -

TF buildings, storage use C60-250 profile punching steel springboard cold bending molding line

TF buildings, storage use C60-250 profile punching steel springboard cold bending molding line -

TF steel structure of fully automatic CNC high speed cold bending production line

TF steel structure of fully automatic CNC high speed cold bending production line -

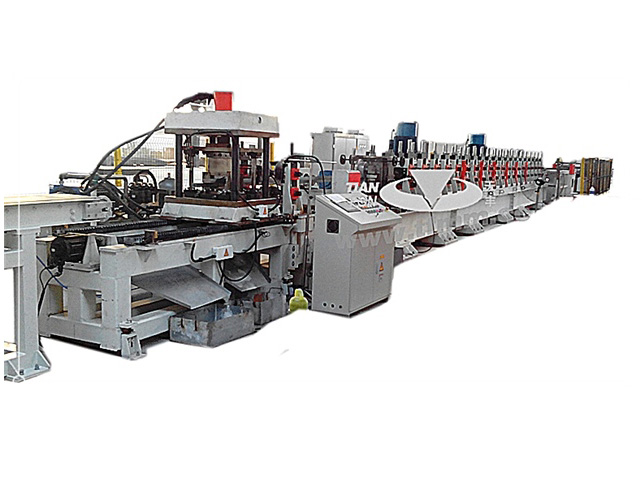

C/Z purlin roll forming machine

C/Z purlin roll forming machine