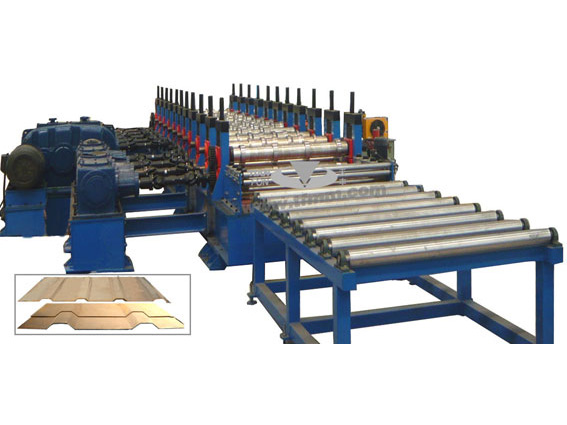

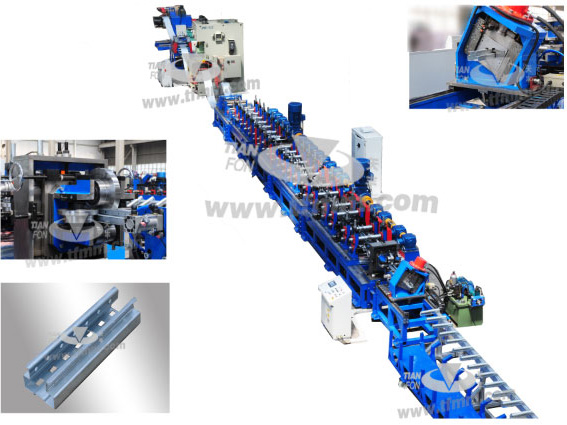

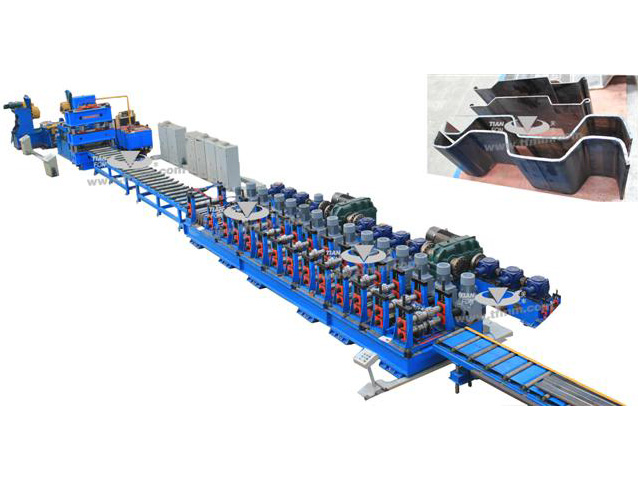

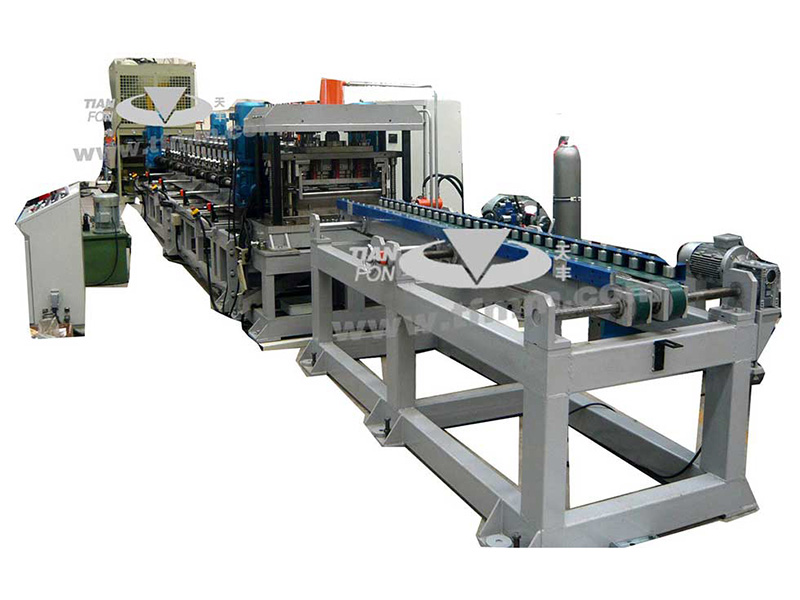

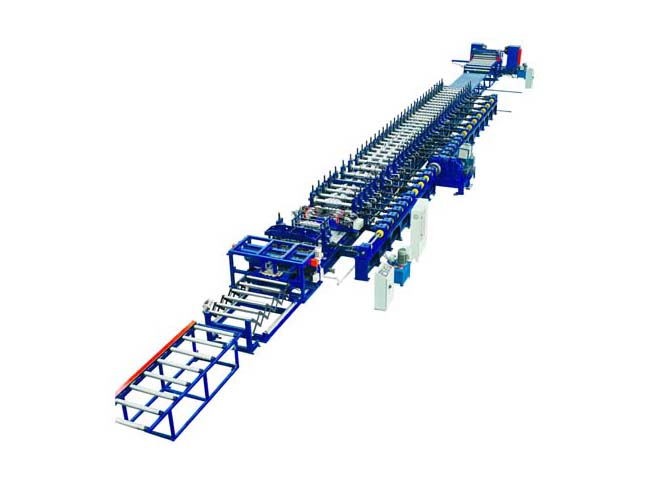

TF piling sheet line adopts quick-change cassettes structure, which means one machine can produce 8 profiles, with the advantages of high speed and automation.

The max. coil thickness: 8mm

The piling sheet is very popular now. In the permanent structures, it is used in the ports, dumps, shore protection wall, retaining wall, breakwater, training dike, dock, flow gate and so on. In the temporary structures, it is used in mountain seals, temporary land expansion, flow break, bridge rail, soil block, water block and sand block when big pipes laying. It is also used in flood fighting.

Main technical parameters:

1. Material: S355JR (hot rolled sheet)

2. Suitable yield strength: σs≤400MPa

3. Coil thickness: 6.0-8.0mm

4. Max. coil width: 1000mm

5. Inner diameter of coil: φ762mm

6. Outer diameter of coil: ≤φ1000~2000mm

7. Coil weight: ≤18T

8. Product length: 2000mm~12000mm

9. Production line speed: 15-20m/min

10. Power: 415V/50HZ, 3 phase 5 wires

11. Total power: about 350KW

Production process:

Loading coil----uncoiling---guiding—leveling---cutting&punching----conveyor---feeding---roll forming----product

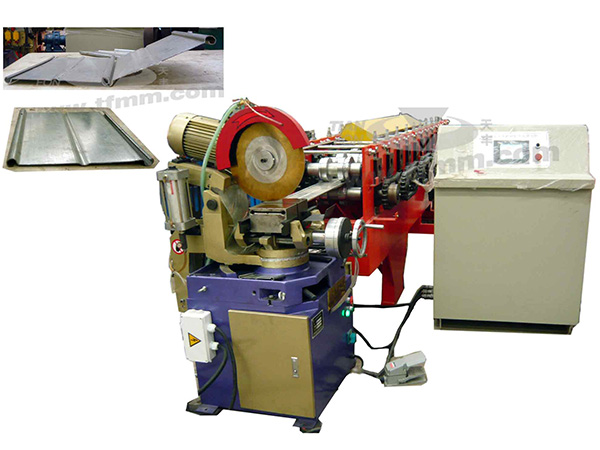

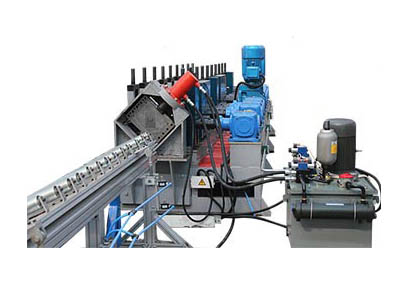

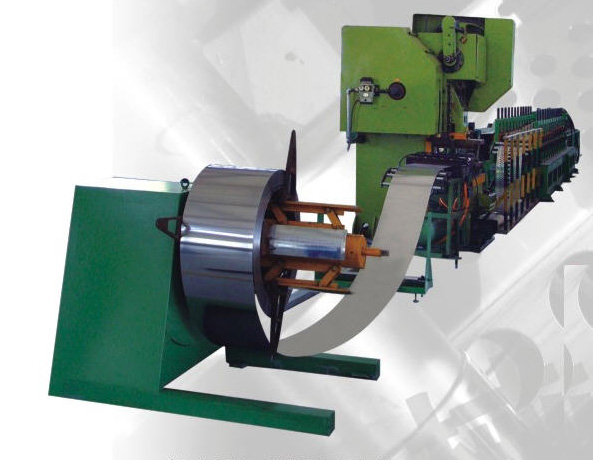

uncoiler part leveler part

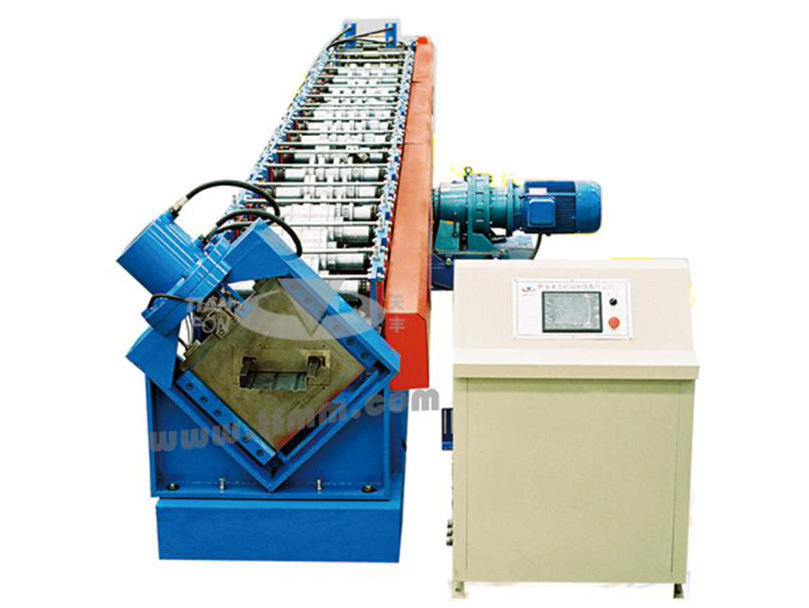

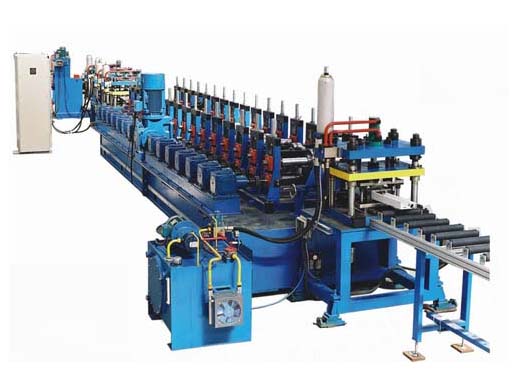

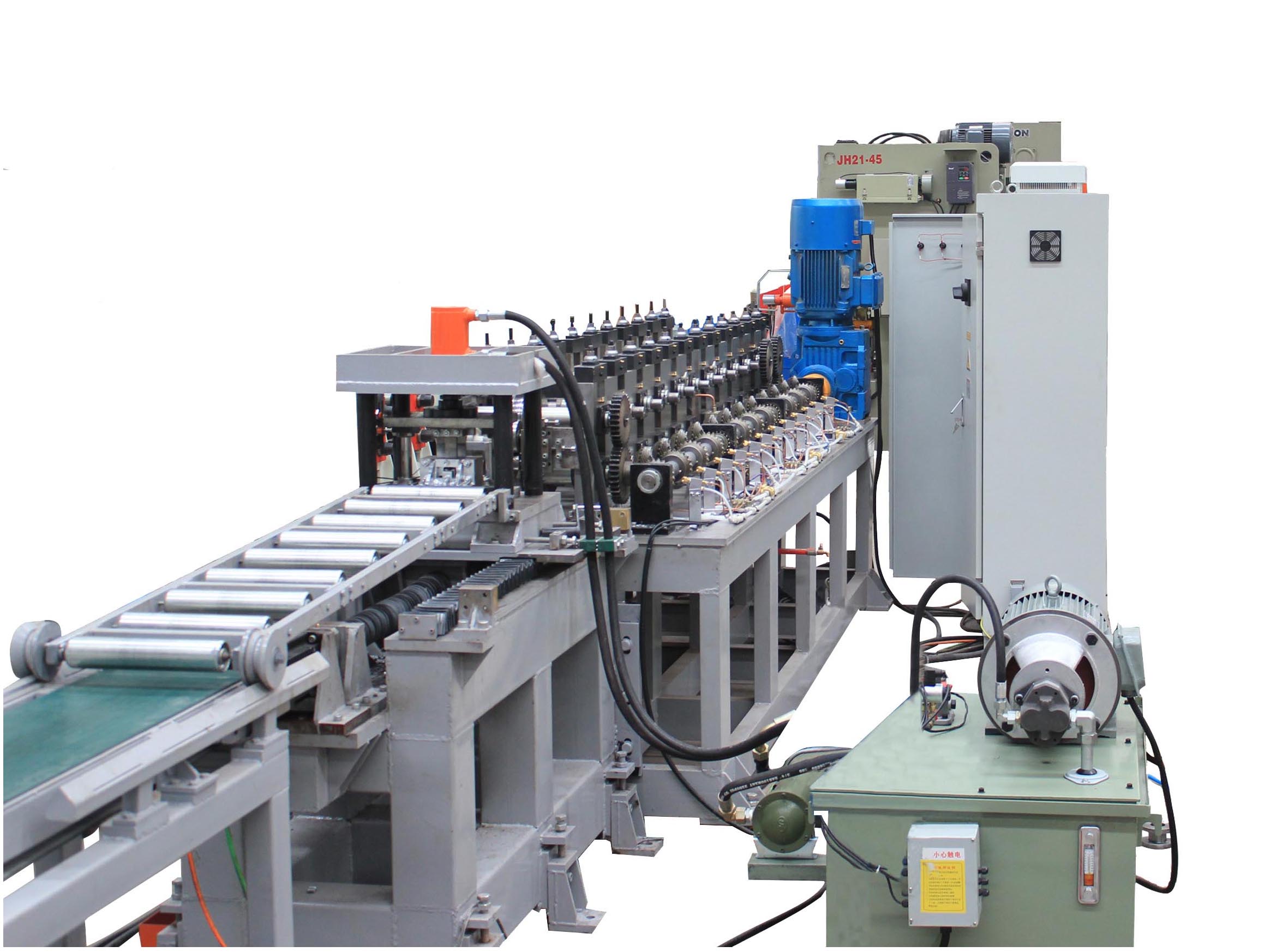

Roll forming machine 1 set

Functions: to roll form different profiles. It adopts absolute cast frame (tempering treatment), the base is welded structure and has stress relief treatment. The roll former adopts raft structure, universal transmits. There is guiding device at front. Fine carbon shaft and easy to adjust and operate.

Roller material: Cr12, HRC58-62 after quenching, with hard chrome on surface.

3 Phase motor (50HZ/415V)drives.

Screw rod adjusts the distance between up and down shafts, and has tight nuts.

Down rollers are located by location surface and has nuts to tight. Up rollers are located by nuts and has inner hexagon screws to tight.

Application

Application

E-mail:contact@tianfon.com

Address:China, xinxiang, high-tech development

zone is a new street, number 369-1

-

Parking equipment side beam cold bending production line

Parking equipment side beam cold bending production line -

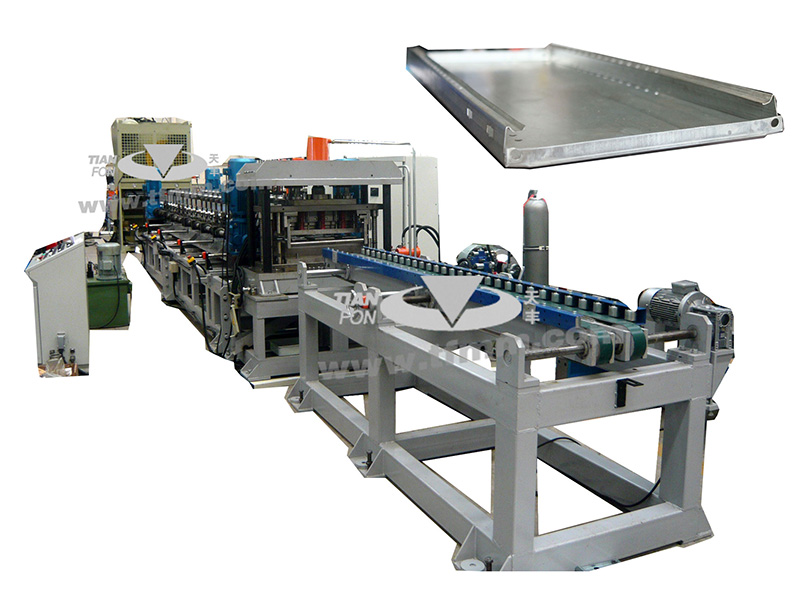

Parking equipment base plate cold bending equipment

Parking equipment base plate cold bending equipment -

Protection plate cold bending equipment

Protection plate cold bending equipment -

Shutter cold bending steel equipment

Shutter cold bending steel equipment -

Cold bending forming equipment for metal door and window frame

Cold bending forming equipment for metal door and window frame -

Metal door plank of cold bending equipment

Metal door plank of cold bending equipment -

Cold formed steel forming production line of solar powered support

Cold formed steel forming production line of solar powered support -

PV stand cold formed steel production line

PV stand cold formed steel production line -

Shelves column profile cold-formed molding equipment

Shelves column profile cold-formed molding equipment -

Box type a series of cold bending production line

Box type a series of cold bending production line -

TF shelves baffle plate production line

TF shelves baffle plate production line -

Light rail, subway conductive stainless steel cold bending production line

Light rail, subway conductive stainless steel cold bending production line -

Metal lampshade automatically cold bending production line

Metal lampshade automatically cold bending production line -

The elevator with hollow guide cold bending steel equipment

The elevator with hollow guide cold bending steel equipment -

Electric cabinet supporting pillar of cold bend forming machine

Electric cabinet supporting pillar of cold bend forming machine -

Cold bending forming machine mining W steel belt

Cold bending forming machine mining W steel belt -

Open book, slitting and winding line

Open book, slitting and winding line -

Uncoiling, leveling, cutting, palletizing production line

Uncoiling, leveling, cutting, palletizing production line -

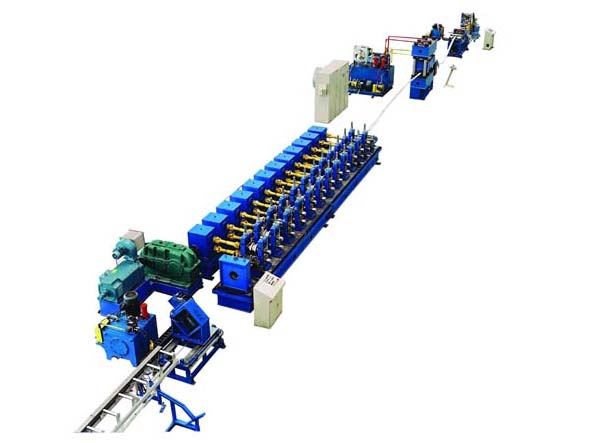

Double row cold bending production line

Double row cold bending production line -

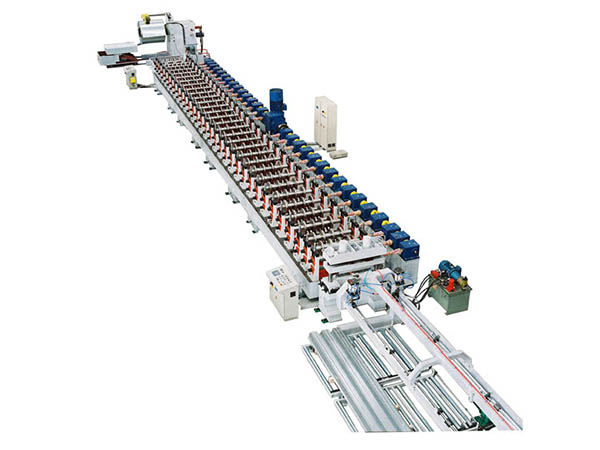

Light steel keel cold bending equipment

Light steel keel cold bending equipment -

Metal packing steel cold bending forming production line

Metal packing steel cold bending forming production line -

Fire dampers cold bending steel molding equipment

Fire dampers cold bending steel molding equipment -

TF crane rail cold-formed molding equipment

TF crane rail cold-formed molding equipment -

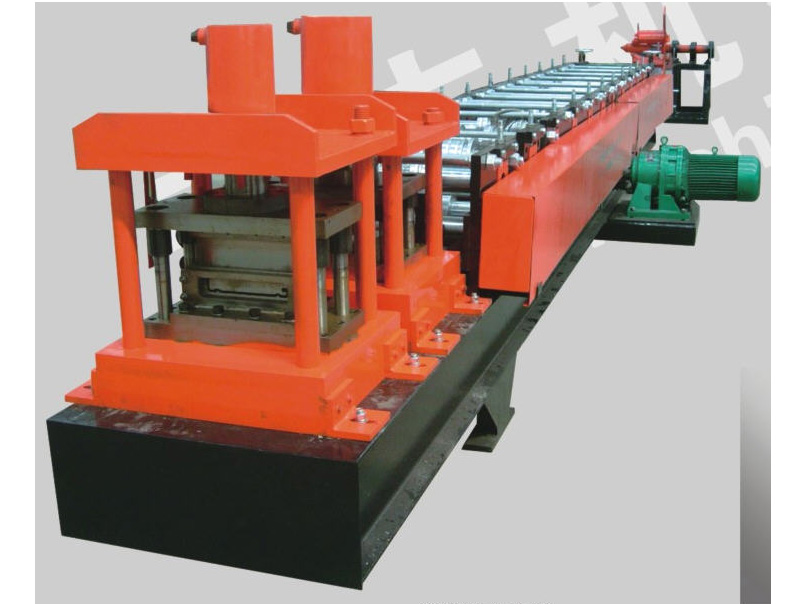

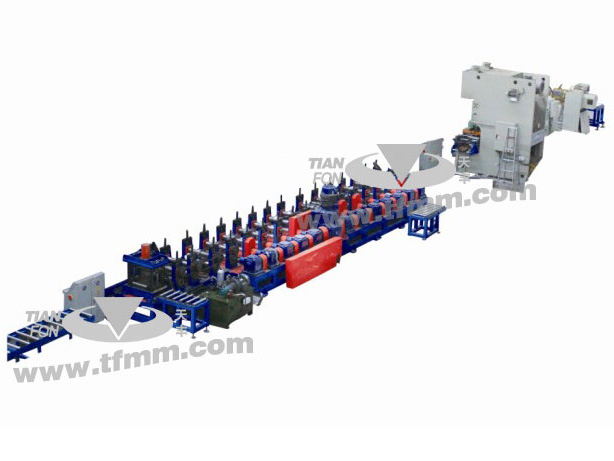

TF piling sheet roll forming line

TF piling sheet roll forming line -

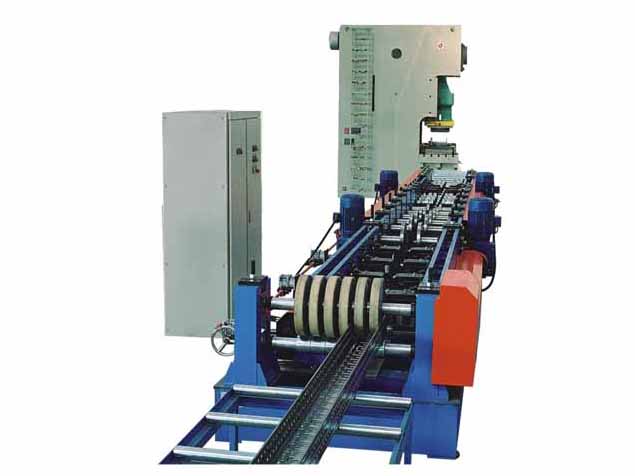

TF30-54 vineyard post automatic punching cold bending forming production line

TF30-54 vineyard post automatic punching cold bending forming production line -

TF sound insulation plate cold bending production line

TF sound insulation plate cold bending production line -

Automotive cover plate, container plate cold bending equipment

Automotive cover plate, container plate cold bending equipment -

The car plate - plate, plate forming production line

The car plate - plate, plate forming production line -

Car plate molding equipment

Car plate molding equipment -

Guide cold bending production line

Guide cold bending production line -

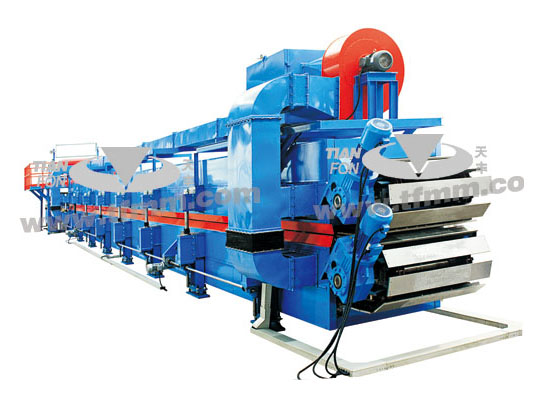

Days beauty FengGe polyurethane (PU) sandwich panel continuous production line

Days beauty FengGe polyurethane (PU) sandwich panel continuous production line -

Day FengGe energy-saving fire phenolic sheet continuous production line

Day FengGe energy-saving fire phenolic sheet continuous production line -

Day FengGe energy-saving fire-resistant phenolic board, polyurethane board

Day FengGe energy-saving fire-resistant phenolic board, polyurethane board -

Tray type cable tray equipment

Tray type cable tray equipment -

Cascade type cable tray equipment

Cascade type cable tray equipment -

Cable tray busway shell cold bending production line

Cable tray busway shell cold bending production line -

Groove type cable tray equipment

Groove type cable tray equipment -

Dust suppression plate production line

Dust suppression plate production line -

ZT24 anode plate forming machine

ZT24 anode plate forming machine -

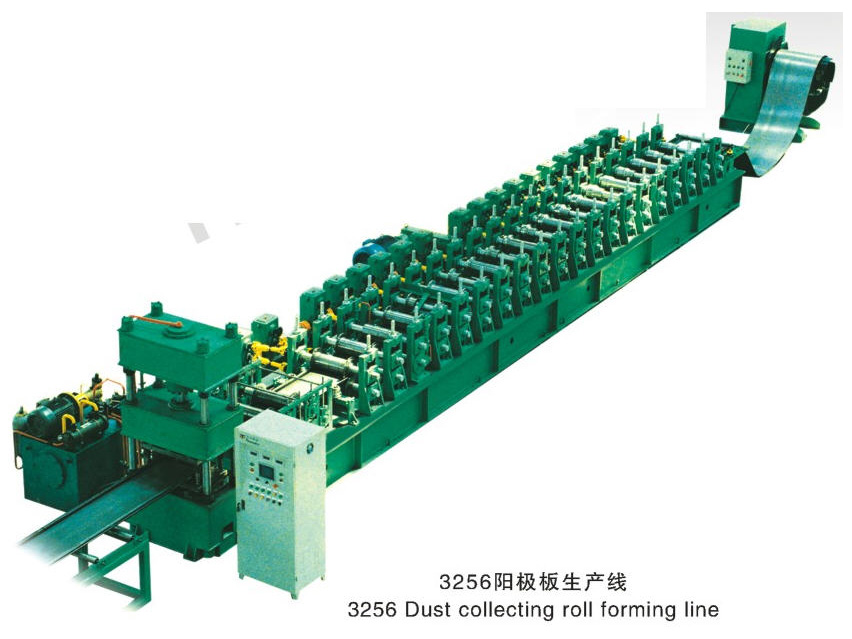

3256 anode plate production line

3256 anode plate production line -

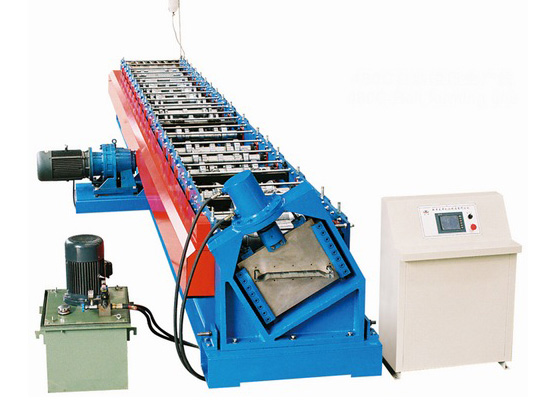

480 anode plate forming machine

480 anode plate forming machine -

Space edge rib cold bending production line

Space edge rib cold bending production line -

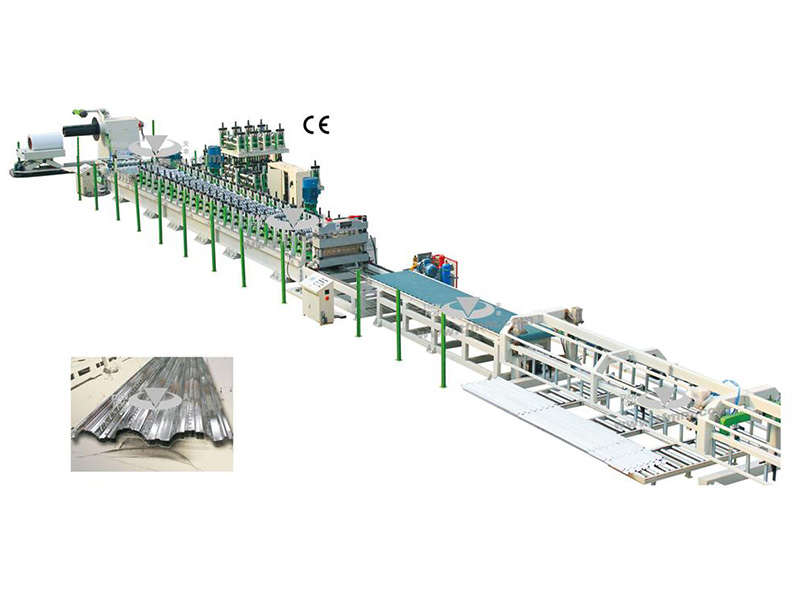

Wall panels, roof plate cold bending forming production line

Wall panels, roof plate cold bending forming production line -

LouCheng plate cold bending production line

LouCheng plate cold bending production line -

Glazed tile cold bending production line

Glazed tile cold bending production line -

Container house profile cold bending production line

Container house profile cold bending production line -

TF buildings, storage use C60-250 profile punching steel springboard cold bending molding line

TF buildings, storage use C60-250 profile punching steel springboard cold bending molding line -

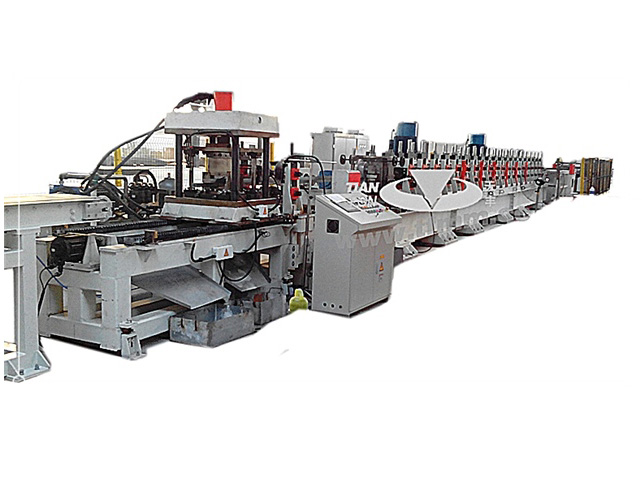

TF steel structure of fully automatic CNC high speed cold bending production line

TF steel structure of fully automatic CNC high speed cold bending production line -

C/Z purlin roll forming machine

C/Z purlin roll forming machine