(1)Production introduction:

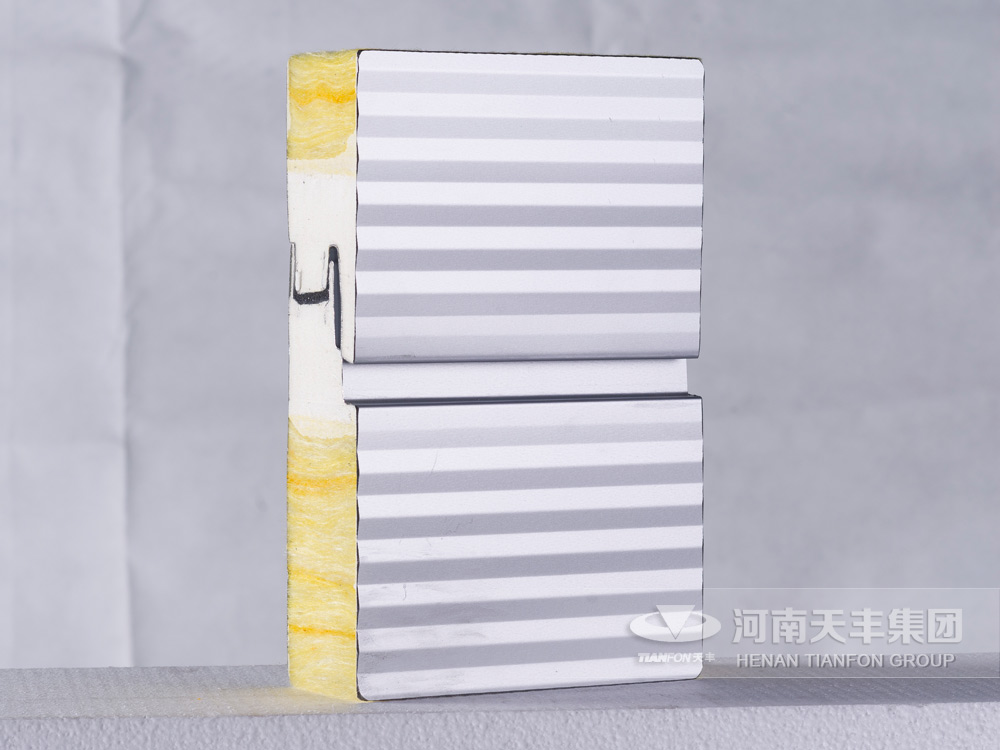

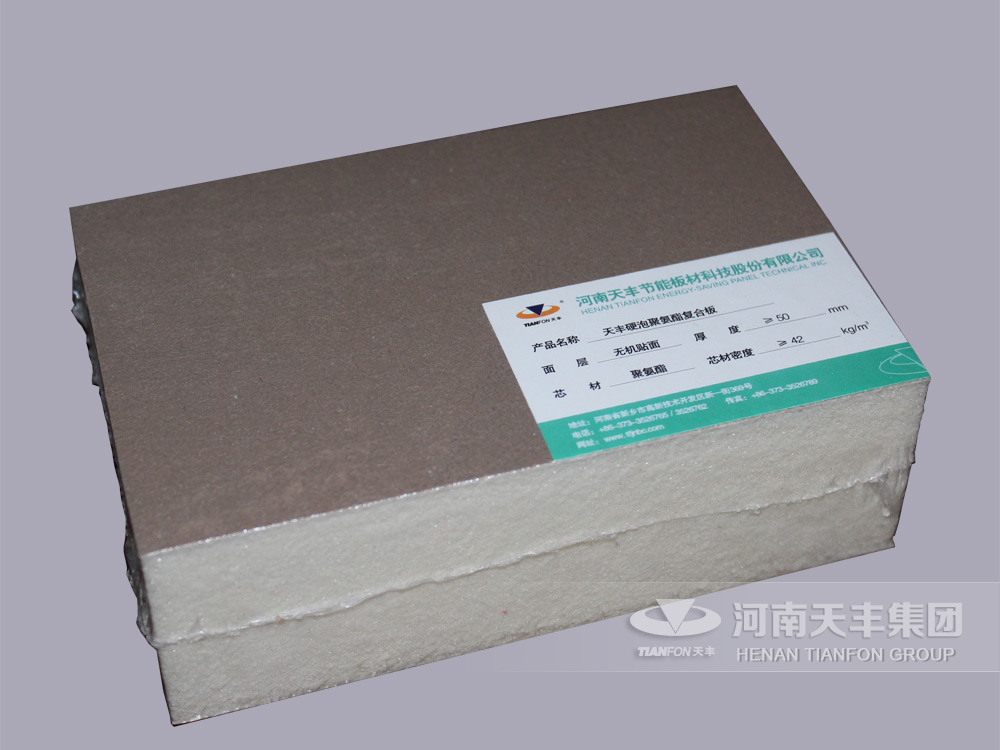

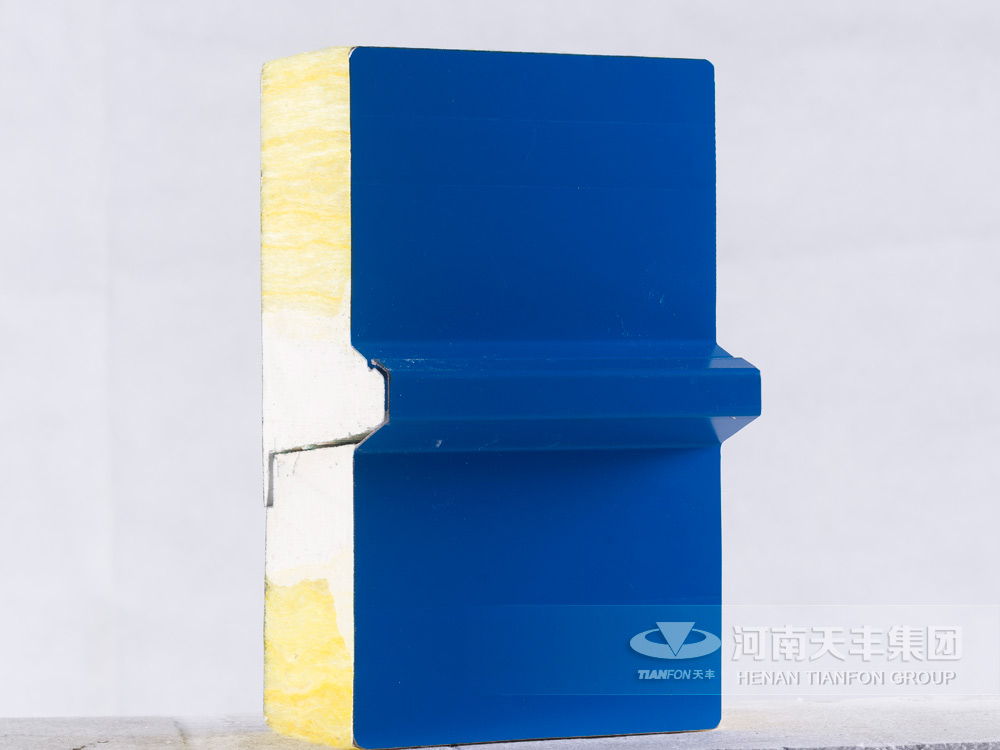

Glass wool composite sandwich panel the better fire-proof insulation panel used for steel structural envelop material accepted at present. It is low thermal conductivity, good load resistance, high bending strength, non-absorbent, anti-corrosion, anti-insect, anti-flaming, high fire proof, temperature resistance. Using the physical property of polyurethane and Unique formula, the polyurethane foaming agent sprays evenly over the color steel plate, molding there layers one-step-modeling polyurethane color steel composite sandwich panel. This new light weight building material perfect matching color steel plate and polyurethane, it is The development direction of lightweight construction materials.

(2)Production feature:

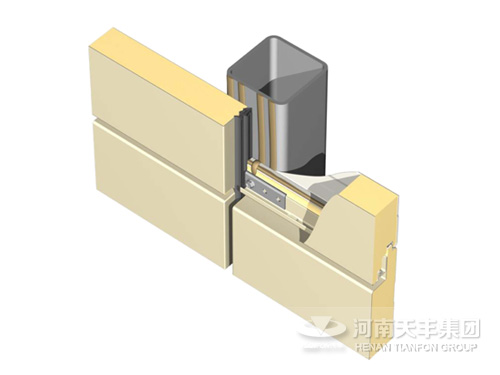

1.Airtight performance: Polyurethane double side-closed glass wool sandwich panel adopts line production process, with the polyurethane’s excellent water proof property, the glass wool panel is moisture proof and anti- water-absorption, it effectively extends their lifespan.

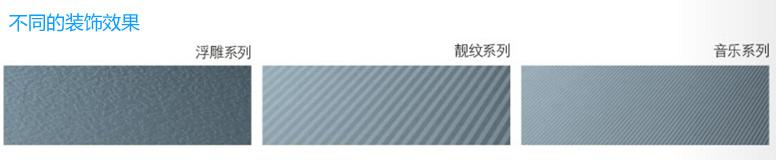

2.Good appearance: The design of joint point adopts Europe standards, with Fruity and smooth appearance, beautiful surface, tight seam, reliable strength, it can prevent the cold-bridge effectively.

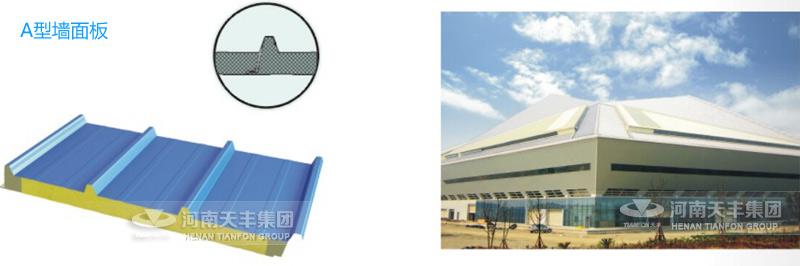

3.Good rigidity: Polyurethane double side-closed glass wool core material bonding into a whole with the upper and down steel plate. Meanwhile, with the wave pressure on the panel surface, the rigidity is far more than the panel composite on-site. The sandwich panel is fixed to the purline by connector, the bulk rigidity is greatly improved. Choosing the glass wool sandwich panel, we can use large purline span, so reduce the consumption by (1/3~2/3).

4.Reasonable hooking way: Using the concealed button, so it avoids water leaking between the roof panel’s joint point.

5.Fasten and reasonable fixing method: Polyurethane double side-closed glass wool roof panel is fixed to the purline using special made M6 type self-tapping screw, so it can effective against typhoons etc. exogenic action. Self-tapping screw is located at the peak of wave between two panels on roof, with special water proof structure, avoids the weak water-proof parts.

6.Short installation period: Without secondary operation on-site, the environment around is clean, it wound not affect other processes. Meanwhile, it can greatly short panel’s installation period, daily installation area can reach 600-800m2.

7.Scratch-proof protection: During the process, the polyethylene adhesive sticker protection foil can be pasted on panel surface, so to avoid the scratch or wear caused during the transport and installation.

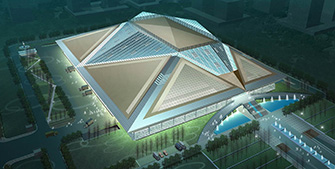

(3)Project cases:

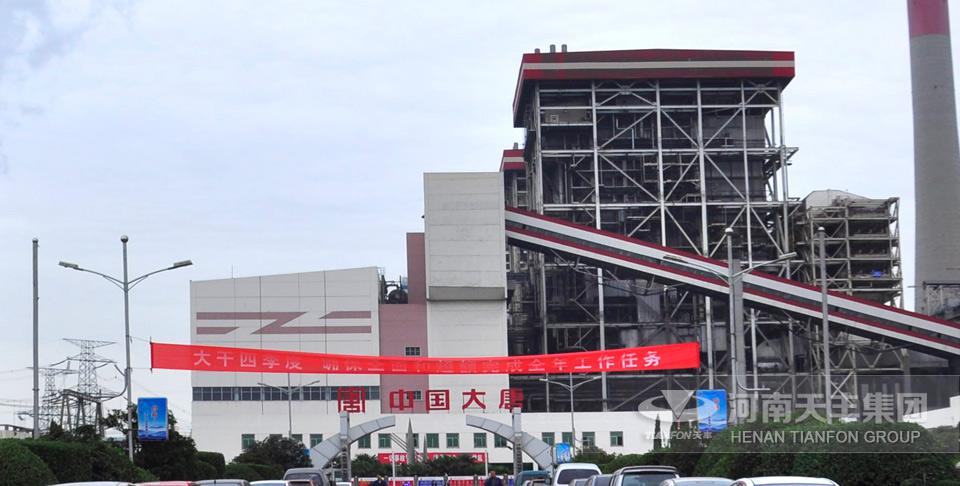

Case 1: China Datang Power Plant

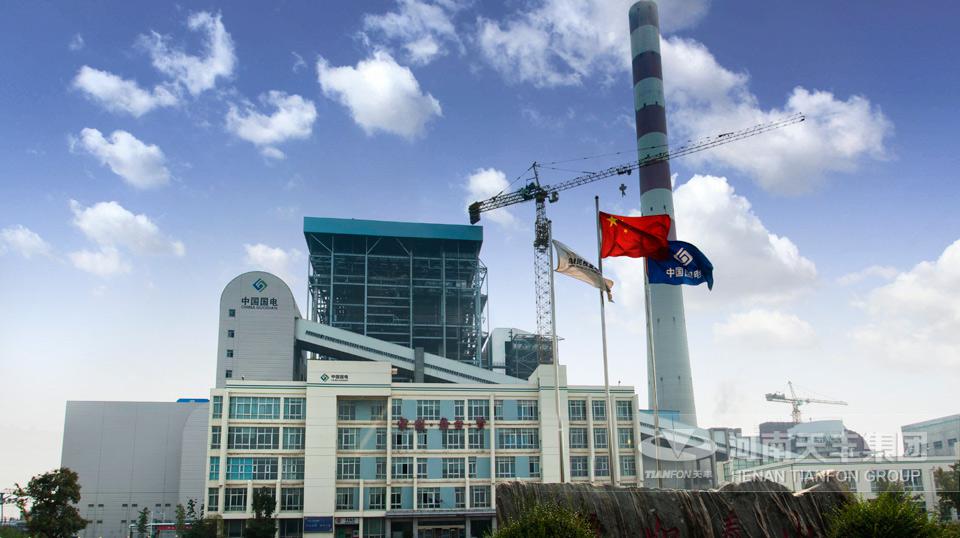

Case 2: China National Power Plant

Case 3: Yingxiao Aviation

E-mail:contact@tianfon.com

Address:China, xinxiang, high-tech development

zone is a new street, number 369-1

-

Solar Photovoltaic Panel-YU panel

Solar Photovoltaic Panel-YU panel -

Glass surface and metallic curtain wall panel

Glass surface and metallic curtain wall panel -

Metallic Curtain Wall Panel

Metallic Curtain Wall Panel -

Composite Air Duct Panel

Composite Air Duct Panel -

Cold chain system special panel----Cold storage panel

Cold chain system special panel----Cold storage panel -

Civilian use external wall insulation panel---Xu panel

Civilian use external wall insulation panel---Xu panel -

Glass wool composite sandwich panel

Glass wool composite sandwich panel -

Rock wool composite sandwich panel

Rock wool composite sandwich panel -

Polyurethane composite sandwich panel

Polyurethane composite sandwich panel